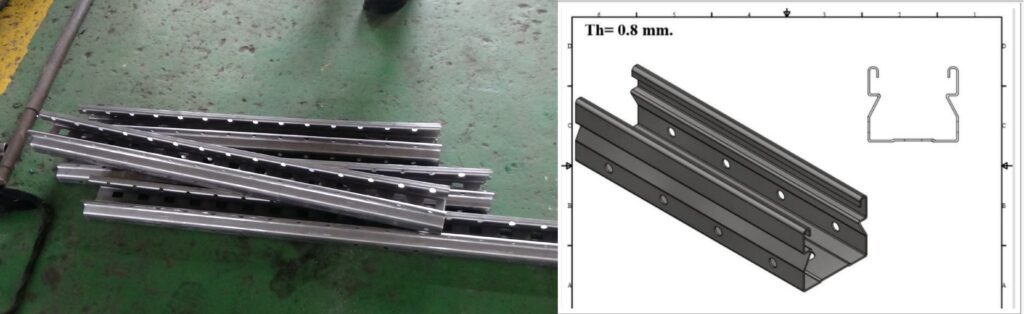

Today, I will introduce an Upright roll forming machine. This machine embodies our wisdom and painstaking efforts. With excellent performance and reliable quality, it has been successfully exported to Pakistan.

Motor shearing double layer machine design:

Advantages of Upright roll forming machine

1. Uncoiling part: Hydraulic uncoiling and feeding integrated machine with 5-ton hydraulic tensioning and brake damping disc for stable material supply during punching.

2. Feeding device: Key transition feeder, smoothly transports uncoiled materials. Adjustable width meets multiple model and width requirements with integrated leveling and feeding.

3. Infeeding part: Ball bearing and guide pillar bridges for thick materials up to 2.5mm. Up and down rollers ensure no scratches and stability.

4. Forming machine: Rectangular structure with bolt connection and 16 Cr12MoV forming rollers. Rollers for feed guidance, dual-group positioning and five-roller leveling for accuracy.