Upright rack roll forming machine is also called storage rack roll forming machine, it is for producing upright racks for warehouse pallet rack system. The sizes and thicknesses is adjustable and customized.

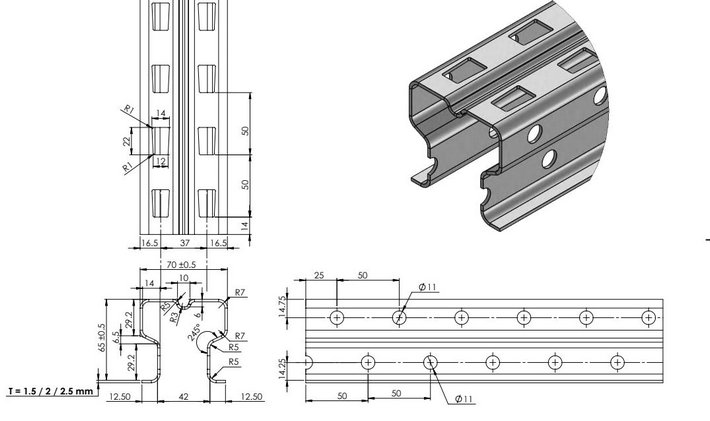

Upright rack (also called Uprights or Upright Columns) varies in sizes and designs and depends on the load capacity and styles. Such as L Shape ( Light Capacity), C Shape (Medium Capacity), Special C Type for heavy Capacity. Holes(Tear Drop Design) and slots are punched during producing so that the load beams can be mounted into the Upright Racks.

Here is a video of the machine working process in detail for your reference:

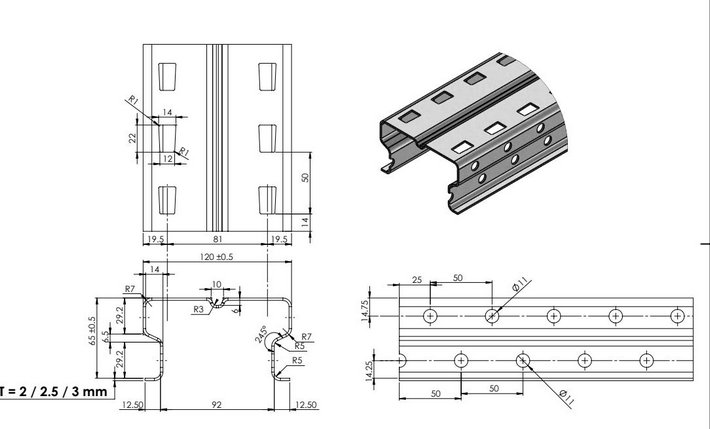

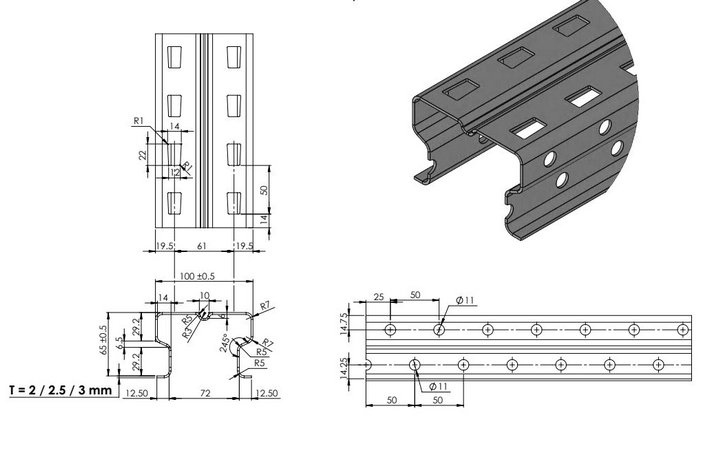

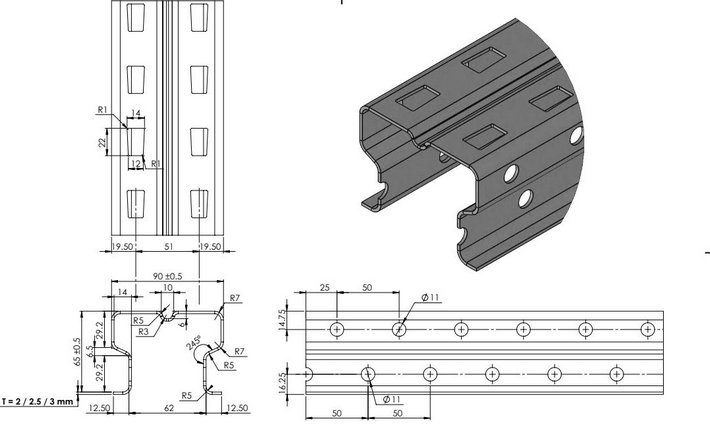

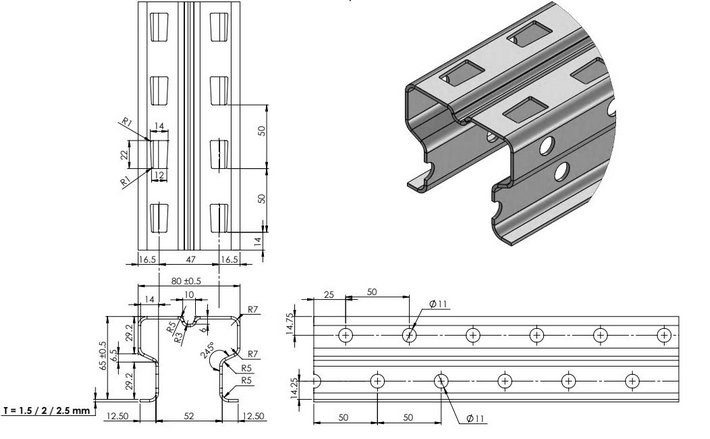

Different sizes of drawing profiles for your reference:

Size: 120/92

Size: 100/72

Size: 90/62

Size: 80/52

Size: 70/42

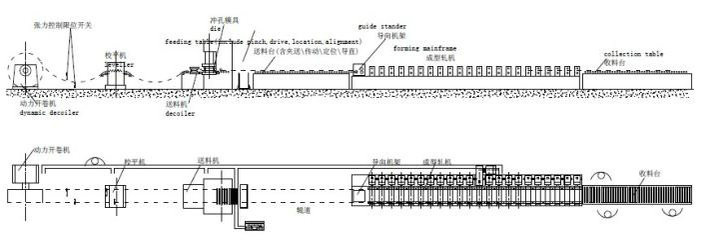

The work flow of upright rack roll forming machine:

Here are some technical parameters of raw materials and the upright rack roll forming machine for your reference:

Raw material

Raw material: Galvanized steel

Material thicknee: 3mm

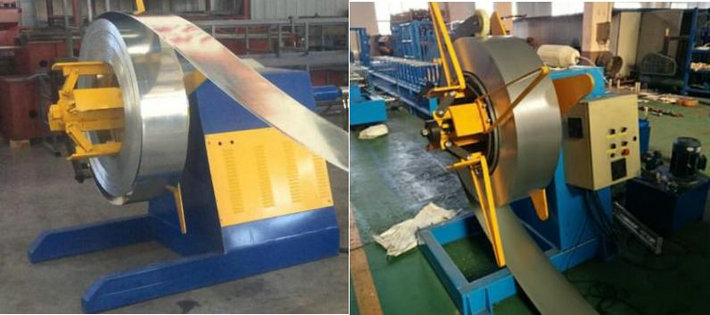

Decoiler

| Work type | Auto type |

| Loading capacity | 3 Tons |

| Coil inner diameter | 450-550 mm (adjustable) |

Leveling machine

| Leveling shaft | 9 pieces |

| Shaft diameter | 70 mm |

| Driving motor power | 5.5 kw |

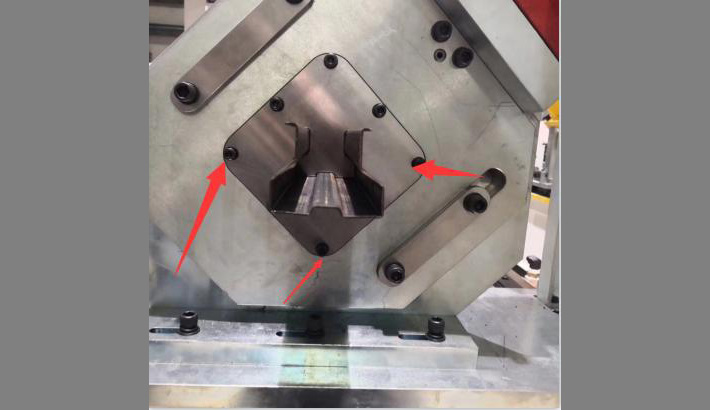

Punching machine

| Working power | 100 tons |

| Hole punch quantity | 8 holes one time |

| Work speed | 60 times per minute |

| Feeder | Servo feeder |

| Punch die | One set |

Roll forming system

| Rolling shaft material | 40Cr |

| Shaft diameter | 70 mm |

| Roller material | Cr12 HRC 56-58 |

| Rolling station | 16 stations |

| Work speed | 0-15m/min |

| Machine frame | Iron casting vertical structure 35 to 45mm, and another middle plate Each layer 20mm middle plate. |

| Machine body | steel plate welded with grinding |

| Motor brand | Siemens |

| Work power | 30 kw (two motors driving) |

| Transmission | Gear |

| Leveling station | 5 shafts |

| Straightening | 4 vertical rollers |

Single side by gear transmission and with two servo motor for size changing:

Whole long shaft, the machine frame will be moved according to the PLC set size. Whole frame will be move on the shaft.

Transmission system

Gear cooling system:automatic cooling circulation tank, which can guarantee not to exceed the gear temperature limit. |

Control system

| Frequency brand | Delta (original) |

| PLC brand | Delta (original) |

| Screen type | Touch screen & buttons |

| Screen language | English/Chinese/Spanish |

| Cut command | Yes |

| Profile length set-up | Yes |

| Batch quantity program | Yes |

Hydraulic system

| Hydraulic system brand | YUKEN standard (made in China) |

| Work type | Hydraulic running cutting |

| Driving method | By pillar type Cylinder |

| Hydraulic motor power | 5.5 kw |

| Cutter material | GB-Cr12 |

| Cutting length tolerance | ±1mm/3m |

| Cutting feature | Low sounds and steady work condition |

Product table

| Length | 6 meters |

| Width | 0.5 meter |

| Work type | Pneumatic |

For different sizes, please change the cutting blades here.

If you need gearbox type, we will design like this: