The main function of the trapezoidal roofing sheet roll forming machine is to produce trapezoidal roof tiles, which are widely used in various building scenarios. This machine is capable of producing tiles with trapezoidal structures, suitable for various building needs. Suitable for roof construction of industrial plants and warehouses, providing good drainage performance and large-span coverage.

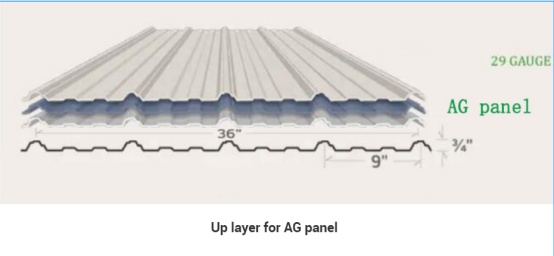

The profile drawing:

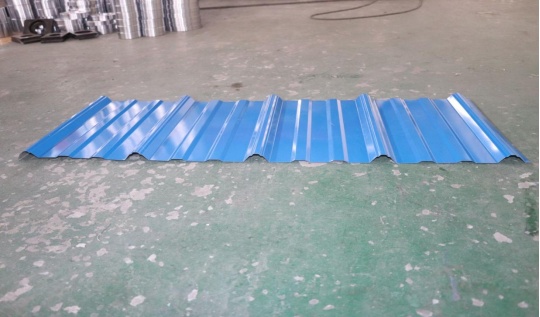

The pictures for the finished product:

Packing list of the Trapezoidal Roofing sheet Roll Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Trapezoidal Roofing sheet Roll Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | PPGI & GI |

| 2 | Raw material thickness | 0.3-0.6mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 21stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains with cover |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel welded |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 4.5kw |

| 14 | Cutting blade material | GB-Cr12 |

| 15 | Cutting tolerance | +/-1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Trapezoidal Roofing sheet Roll Forming Machine:

1. Durability and stability:

Trapezoidal Roofing sheet Roll Forming Machine typically have sturdy structures and durable components, ensuring stability and long lifespan.

2. Efficient production capacity:

These machines are designed for efficient production and can meet the needs of large-scale production.

3. Flexibility and Customization:

Many Trapezoidal Roofing sheet Roll Forming Machine have customizable voltage and color options to adapt to different production environments and user needs.

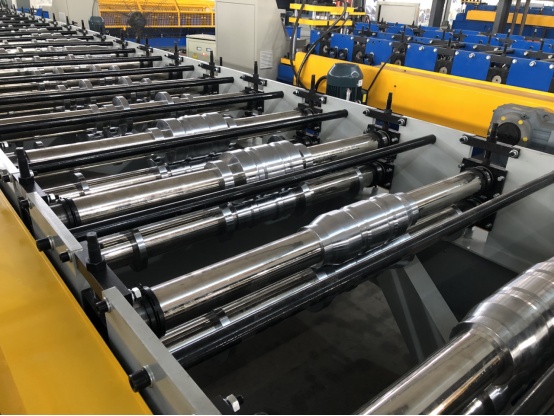

Machine photos: