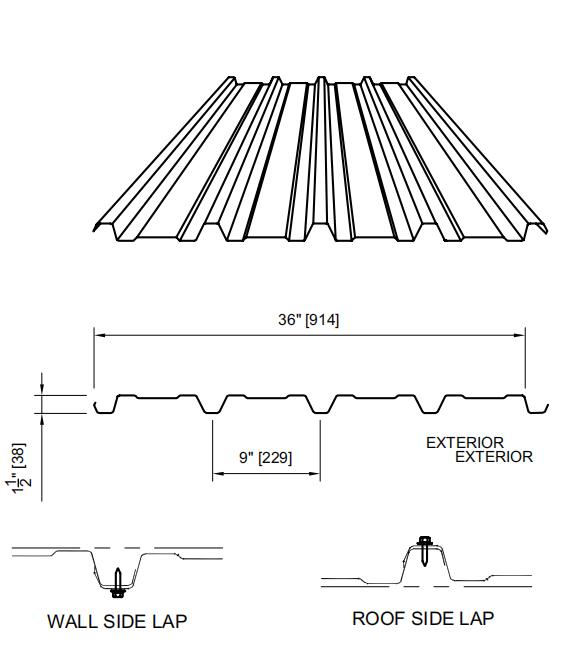

The TR4-36 profile features four 1 1/2” [38 mm] deep ribs on 9” [229mm] centers which gives an attractive, standing rib appearance. TR4-36 side laps in the high cell when used as a wall or roof panel. All Exposed Fastener wall panels may be installed in a variety of rainscreen applications to form a complete wall system. This profile is quite popular in South American.

Here is a video of TR4-36 machine for your reference:

Here is the TR4-36 drawing profile for your reference:

TR4-36 metal roofing sheet rolling forming machine:

This machine is designed based on knowing fully requirements of this Tr4 drawing profile. The metal roofing sheet machine, we design like this:

Main components of the machine:

| Description | Quantity (set) |

| 6Tmanual decoiler | 1 |

| Guiding device | 1 |

| Hydraulic pre cutter | 1 |

| Forming system | 1 |

| Transmission system | 1 |

| Hydraulic guillotine&punching | 1 |

| Support table | 2 |

| Hydraulic station | 1 |

| Control box | 1 |

| Spare parts and tools | 1 |

General Parameters of machine:

| NO | ITEM | Parameter |

| 1 | Forming Speed | Max18m/min(depend on quantity of punching) 10-15METERS/MIN depends on the quantity of punching holes |

| 2 | Forming station | Around 18 groups |

| 3 | Total Power | About 5.5 KW |

| 4 | Total Weight | About 6500kgs |

| 5 | Voltage | 220v,50hz,3p |

| 6 | Diameter of shaft | 70/80mm |

| 7 | Installation Size | 9.5 * 1.2 M*1.5 |

Main parts Material:

| No | Item | Parameter |

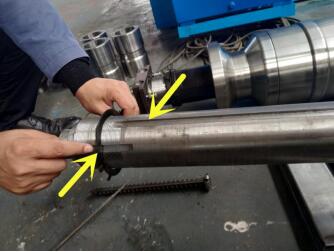

| 1 | Forming Shaft | s45c with grinding process and heat treatment HRC28-32,twice CNC |

| 2 | Forming Roller | s45c with vacuum heat treatment with hard chrome coatingHRC50-52 |

| 3 | Cutting Blade | Cr12MoV with hard treatment |

| 4 | Control System | PANASONIC PLC, others are Schneider etc. |

| 5 | Electrical motor | China quality brand |

| 6 | Touch screen | Win view |

| 7 | PLC | Panasonic |

| 8 | Rely | Schneider |

| 9 | Encoder | Omron |

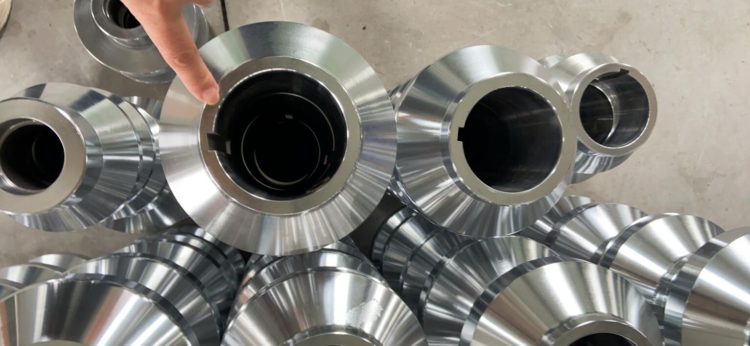

Main parts of our machine:

Roller: We equipped each roller with a keynote for making the roller and shaft tightened.

Spacer: We use seamless pipe for this part and the material thickness is much more thicker so as to ensure the long life and high accuracy of the machine. This kind of spacer is corrosion-resistant and can better protect the shaft.

The main rollers part, we use the material GCR15 quenching at 58 degree to make sure the hardness of rollers. For some bigger rollers, we will do the quencing even if two or three times.

PLC: The PLC control system is touchable and makes response quickly. It can save time and lower labor cost.

Our machine is easy to install. We also have technicians to guide you how to install.