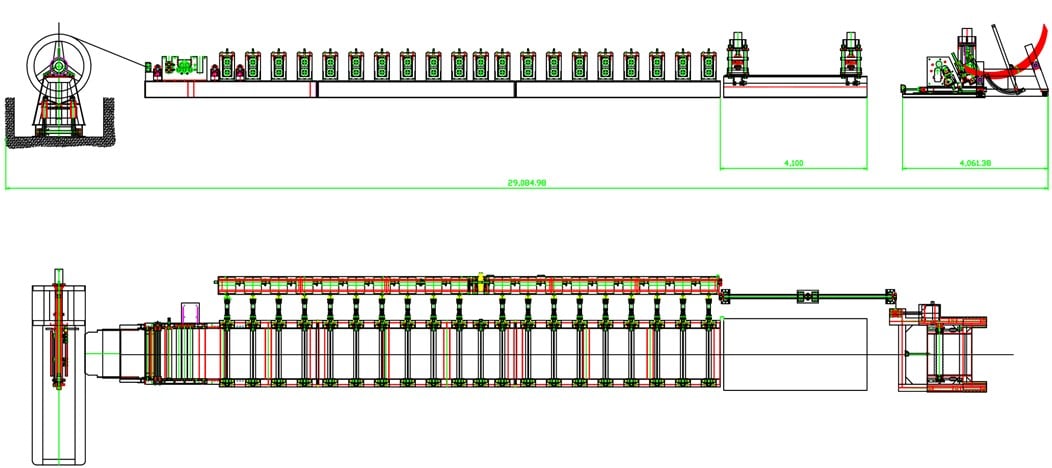

The roll forming machine production line including :7 tons hydraulic de-coiler, feeding leveling system, front hydraulic cutting, roll forming machine, hydraulic punching machine, online crimping machine, corrugated board hydraulic shearing machine, finished product discharging table, and hydraulic station, electronic control system and other components.

Cantilever internal structure.Drive the tension through the hydraulic cylinder,Hydraulic motor traction coil rotation,Proximity switch controls discharge speed.Capacity is 7T,Sheet width 1250mm,Tension range:¢500-620mm.

Coil is on the feeding car V table, Hydraulic cylinder drive lifting mechanism,Raise the roll to the center of the tensioning axis, Feeding car along the base rail of the discharger,Driven by the reducer motor for lateral displacement, Put the roll on the tensioning shaft and do the pre-order work for the tensioning coil.