For the steel structure building, if we want to make a multi story or single story steel building there are many components that you have to consider. From the frame, walls, roof, floor and so on, the engineer has many factors that need to be accounted for. Metal decking floor system is one of the system. There are many ways to design and construct a stronger metal decking floor system. Here we take an machine of metal decking rolling machine for Colombia for example.Purlin machine

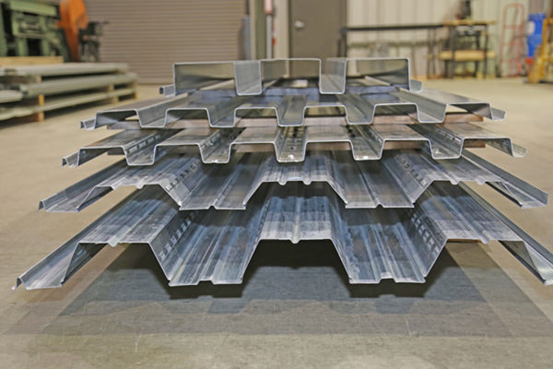

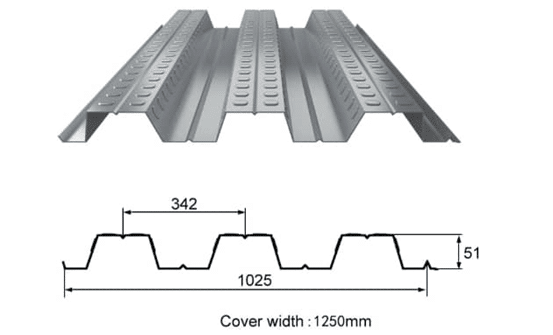

Most of your options to make the floor system stronger require adding extra weight, which has an impact on other aspects of the building such as the steel framing. Here is the metal decking drawing profile for your reference:

How metal decking is used in our life?

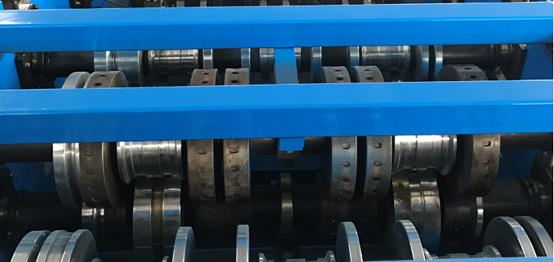

Zhongtuo Steel Structure Floor Deck Roll Forming Machine:

Steel Structure Floor Deck Roll Forming Machine for Colombia parameters for your reference:

Technical Proposal

- Material: Steel, GI, hot rolled or cold rolled

- Material Thickness: 0.7-1.2mm or some to 15mm, it is also okay.

- Main roll forming machine Power: 15KW*2sets

- Motor: Siemens

- Forming Speed: 12-13m/min

- Machine size: 14000*1700*1500mm

- Machine weight: 15000KG

- Main Parts of metal decking machine.

1.5T Hydraulic Decoiler with cart or you can use manual or 10 Ton.

- Hydraulic feeding table

- Hydraulic sheet pre-cutting unit

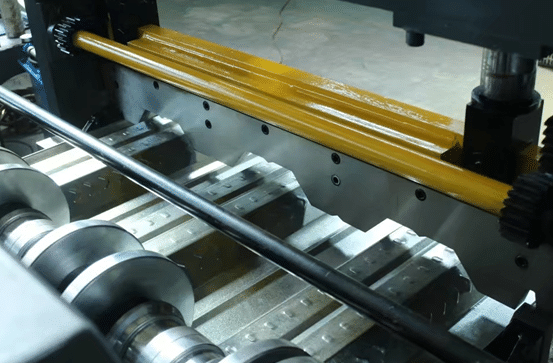

- Roll Forming System

- Hydraulic stop cutter

- Control system

- Output table

More detail pictures of Steel Structure Floor Deck Roll Forming Machine:

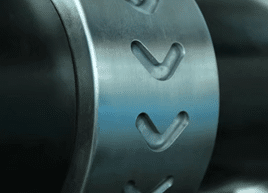

Embossing rollers:

As to the cutting part of the metal decking machine:

Here are some metal decking machine pictures for your reference: