ZhongTuo Machinery is a company that is professional in manufacturinig the steel floor deck roll forming machine. The steel floor deck roll forming machine is used to produce high-quality steel floor decks. The steel floor deck is also called floor bearing steel plate. This kind of floor deck is applied in supporting concrete or insulating membrane of a roof. It is developed to provide a structurally efficient product for use in roof and floor systems. The floor has the fllowing features: high peak and high strength with a low cost. If you are interested in our machine, please click here to contact us.

Here is a video of the machine operation for your reference:

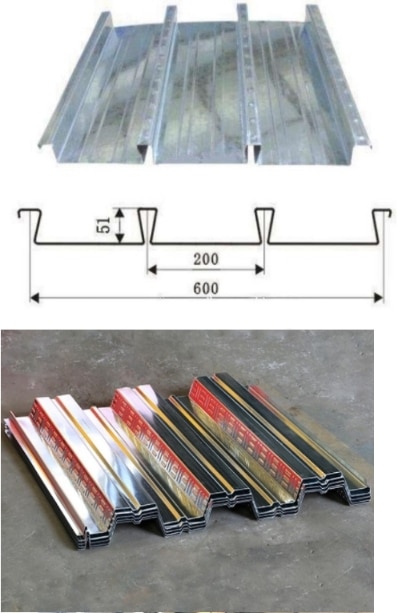

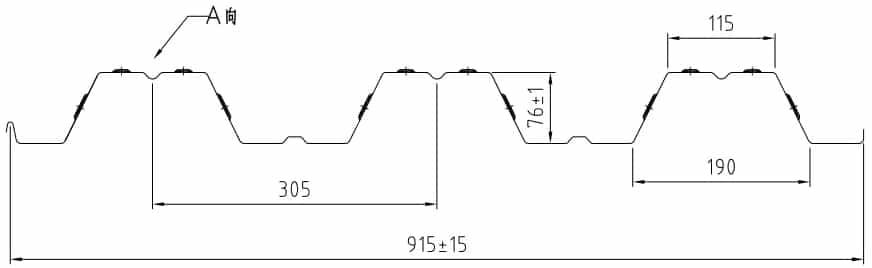

Here are pictures of the drawing profile and finished products for your reference:

Advantages of steel floor deck roll forming machine:

- Our machine adopts solid shaft and H-shaped steel as the underframe, so the machine can have long-term production life.

- The rollers of our machine are made from famous brand machine tools, ensuring the high accuracy of the rollers.

- The cut blade frame of our machine is stress-relieved to ensure that it will not deform during the long-term production line and.

Here are pictures of the machine for your reference:

More details for your reference:

- We use the double chain for big power and long time to use.

- Strong shaft with keynote.

- Leveling with gear outside and with the protection rollers.

- 120mm strong embossing roller with protection shaft.

Technical Details

| Machine Specifications | |

| Weight | About 15000kgs |

| Size | About 16m x 1.8m x 1.5m (length x width x height) |

| Suitable Raw Material | |

| Material | Galvanized or Galvalume Coils |

| Thickness | 0.8-1.2mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Diameter of forming rollers shafts | 95mm |

| Roll Forming Speed | 10-15/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 3x11kw |

| Hydraulic unit motor power: 5.5kw | |

| Electric voltage | According to customer’s requirement |

Working process of the machine:

Application of finished products: