Standing seam rolling forming machine

Standing seam rolling forming machine is designed to make the standing seam in batch fully automatically which is consist of Uncoiler, Roll Forming Unit, Cutoff Unit. Controlled System, etc. Here are some popular design of standing seam in North American for your reference:

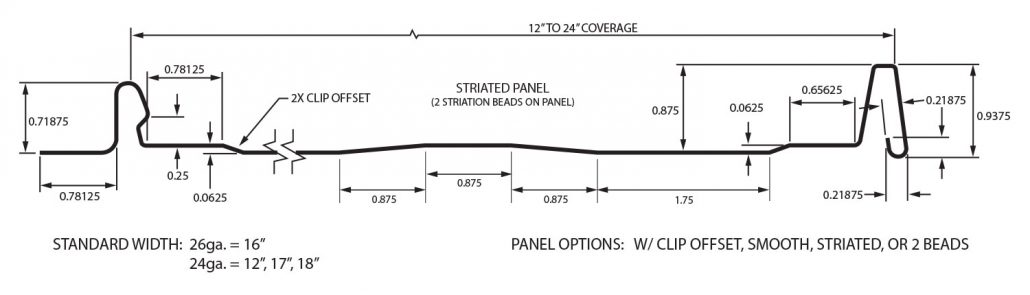

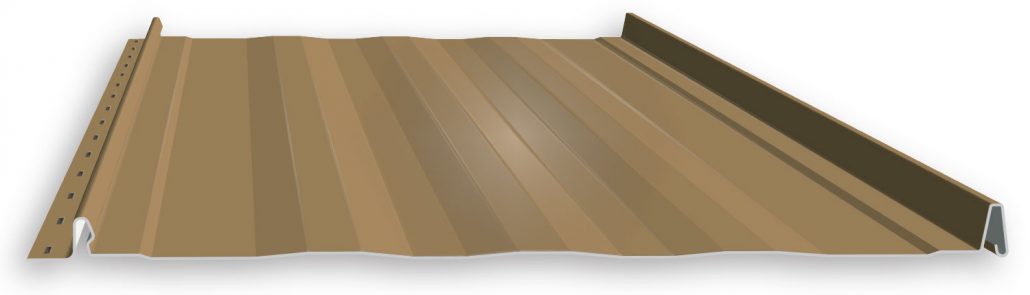

The first one we call it as FF1 Panel

The second one we call it as SL15 Snaplock Panel:

Where is the Standing Seam Roof System?

Standing Seam Roof System is a new advanced roof system which can be seamed each other through ribbed metal plates. The materials are usual aluminum magnesium manganese alloy plate, can also be aluminum-zinc plate. Our stand seaming machine is able to a width of 300-600 standing seam panels.

The main structural forms are as follows. First, the T-type fixed stand (usually made of aluminum alloy) is fixed on the main structural purlin. And then the Standing Seam Panel is fastened to the head of the fixed stand. Finally. And the workers can use the automatic seam machine or manual seamed tool to seam the edge of the standing seam panel together. Vertical locking system is a newly developed waterproofing technology. Which has the characteristics of advanced fixed mode, free expansion of temperature deformation, good wind pressure resistance, good corrosion resistance and flexible field production mode. And which ensures its tight waterproof function. And because the plate rib is upright, the drainage section is larger than the ordinary board, it can guarantee the waterproofing performance of the roof slab under the condition of transverse tilt So it is an advanced roof waterproof system, and has excellent waterproof performance.

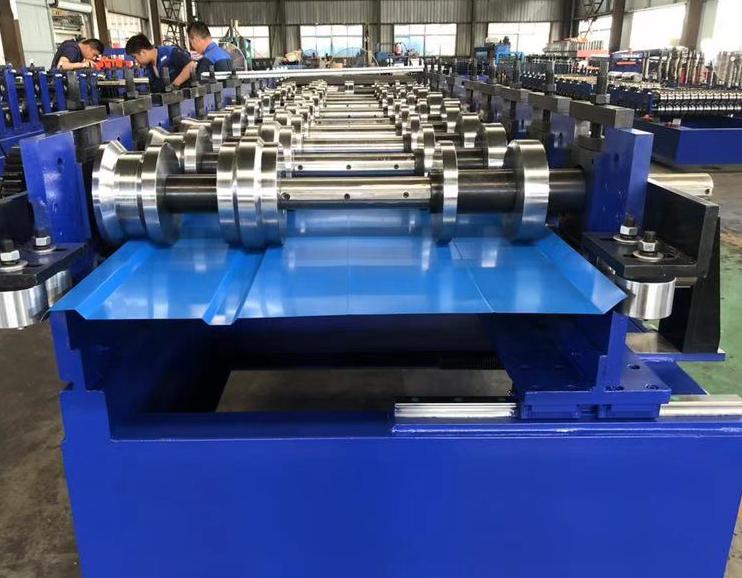

Here are some standing seam machine pictures we sent to Korea for your reference:

In conclusion, Standing Seam Roof Panels is more and more famous for steel buildings. Easy to assemble, long time use, etc.

Standing Seam Roll Forming Machine System with 5 Ton Automatic Uncoiler or you can choose 5 ton manual decoiler, rolling forming machine with the before shearing system for adjusting to any length. The machine we made could be used to adjust the width from 400 to 800mm.

Sometime for the standing seam machine, you may also need the automatic seam machine and others. Normally the standing seam machine supports the coil of aluminum, PPGI, GI, thickness: 0.3-0.8mm, width: 400-800 mm and the machine working speed can reach 12-20 m/min. The rollers Material: ASTM 1045, quenched and tempered and shaft Material: ASTM 1045, 75mm Diameter, forming Stands: 18 and cutter Blade Material: CR12

Another type of standing seam rolling forming machine.