The main function of the Self-lock Standing Seam Profile Roll Forming Machine is to produce vertical seam roof tiles. This machine can manufacture roof tiles with vertical seam structures through specific molds and processes, suitable for the roof laying needs of various buildings.

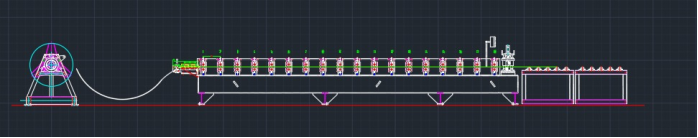

The pictures for the product:

working flow of self-lock standing seam profile roll forming machine:

Main components of self-lock standing seam profile roll forming machine:

| Item | Description of Item | Unit | Quantity |

| 1 | 3T hydualic decoiler | set | 1 |

| 2 | Main roll forming machine | set | 1 |

| 3 | Hydraulic Cutting system | set | 1 |

| 4 | PLC control station | set | 1 |

| 5 | Product receive table | set | 1 |

| 6 | Spare parts | set | 1 |

The following is detailed introduction of each main elements of this self-lock standing seam profile roll forming machine:

Part 1: 3T Hydraulic decoiler

1.Function:Supporting the coils and doing uncoiling.

2.Capacity:3 tons

3.Coil inner diameter:450-550 mm

4.Coil width:650mm

Part 2: Main roll forming machine

1.Shaft material:45# STEEL with quenched and tempering

2.Shaft diameter:70mm, solid shaft

3.Roller material:High grade 45# steel, surface chromed thickness 0.05mm

4.Roller station:20 stations

5.Work speed:About 0-15m/min

6.Machine body:350H steel welded

7.Bearing :Chinese famous brand Harbin

8.Work power:5.5 kw

9.Transmission :By double chain, with chain cover

10.Voltage:380V,50Hz,3 phase (customize)

Part 3:Hydraulic cutting system

1.Work type:Hydraulic

2.Driving method:By Cylinder

3.Motor power:5.5 kw

4.Cutting blade material :GB-Cr12 mould steel with quenched treatment

5.Cooling system:By fan

Part 4: PLC Control system

1.PLC and Touch screen:Delta, wold famous brand

2.Electrical components:Schneider

3.Operating language:English and Chinese(or as requested)

4.Function:You can set the orders on this part,changing product length and quantity,it is really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.