ZhongTuo can offer you high-end roller shutter door machine with a quitely reasinable price. The roller shutter doors produced by our designed machines are made from steel. They are featured high-strength and good stability. The raw materials generally are 0.6-1.2mm GI steel or PPGI steel. The machine can produce many sizes of roller shutter doors. And if you hace your own needs of machines, you can contact us and let us know your idea, then we can design and manufacture customized machines for you.

Here is a video of popular roller shutter door machine designed for Algerlia which can work 25 meters pre minute.

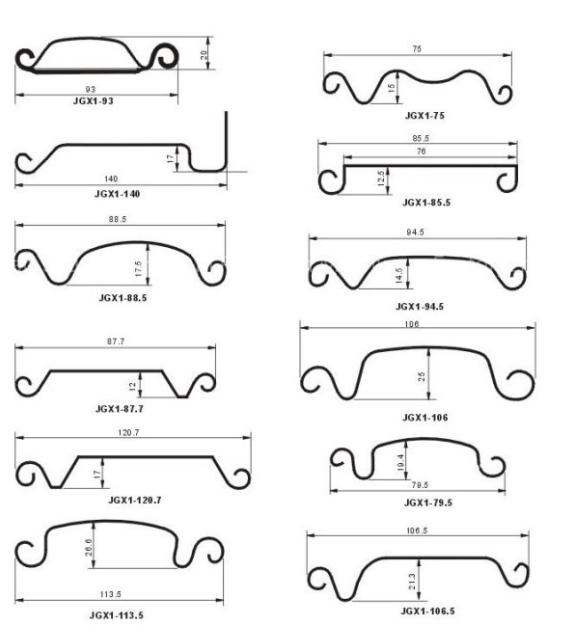

Here is a picture that shows different types of roller shutter doors:

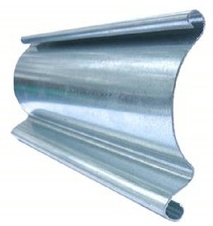

Take this finished product for example for your reference:

Usage of finished products:

- Self-locked roller shutter

- Roller shutter guide

- New type roller shutter

- Roller shutter door panel

There are pictures showing the applications of finished products for instance:

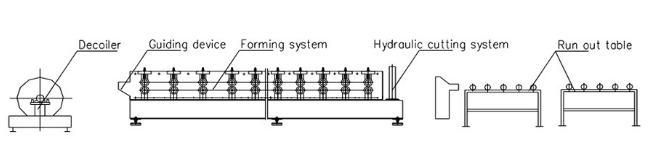

Working flow of the machine:

Main features of roller shutter door machine:

- The machine is very simple to install and maintain.

- The raw materials make sure that the machine enjoys long life and good stability.

- We have embraced major components of the machine thar are fiom world-famous brands, such as eletronic system, controller, and so on.

- The machine is fully automatic.

- We design the machine in a beatiful appearance and meet your different requirements.

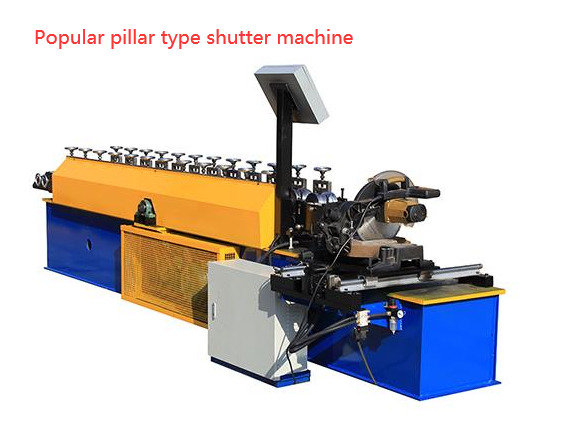

There are some pictures of the major parts of our machine for your reference:

Technical Parameters of a Roller Shutter Door Roll Forming Machine:

- Uncoiler: Manual Uncoiler, Automatic Uncoiler;

- Loading Weight: 5Tons;

- Inner Diameter: 480-520mm;

- Outer Diameter: Max 1250mm;

- Raw material: Pre-painted steel coils;

- Material thickness: 0.4-0.8;

- Material width: 1219mm;

- Main Structure of the Machine: 36# “H” Beam Steel;

- Rolling Stations: 18 stations (subjected to final design);

- Forming Speed: 0—12m/min (not including cutting);

- Diameter of Shaft: 70mm;

- Material of Shaft: 45# steel with heat treatment;

- Material of Roller: 45# steel with quenching and chrome coating treatment;

- Transmission: Chains-bracket;

- Motor Power: 5.5KW (subjected to final design);

- Material of Cutting Mold: Cr12 Steel with quenched treatment HRC 60-62;

- Cutting Length and Quantity: Clients can set the required length and quantity on the PLC touch screen;

- Hydraulic Pump Power: 3KW (subjected to final design);

- Tolerance of Cutting Length: +/-2mm;

- PLC Control Box: 700mmx1000mmx300mm;

- Computer Control System: Panasonic PLC;

- Encoder: Omron Brand;

- Voltage: 380V, 50Hz, 3 phase.