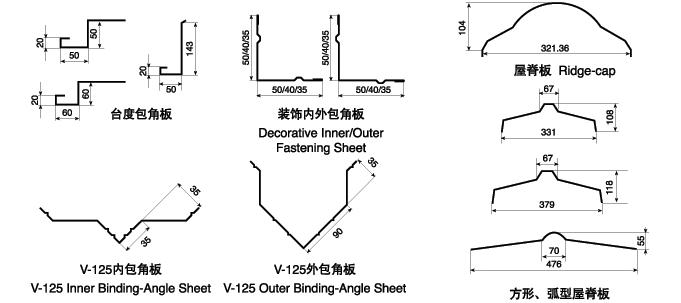

Ridge cap machine is designed to produce metal roof ridge caps that are used as roofs for residential and commercial buildings. Houses built with metal ridge caps look much more attractive and vintage. So, these products are widely used for buildings. Based on this fact, Zhong Tuo mechinary has designed machines to produce several types of ridge caps as follows:

What’s ridge cap?

Ridge cap is a special shingle that is designed to defend the harsh wind hitting the ridge of a roof. Therefore, A ridge cap should be thicker than a regular shingle and pre-bent.

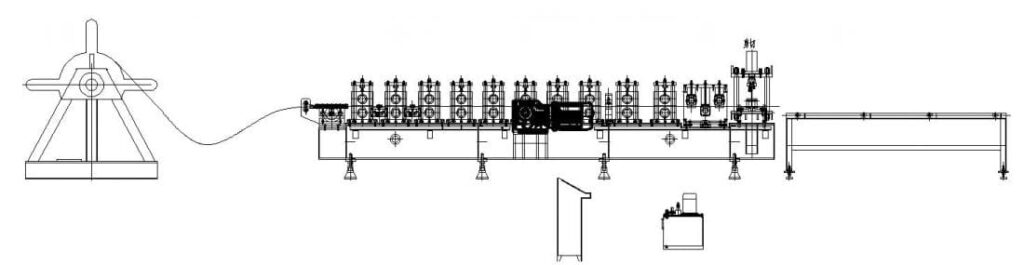

Picture of this machine:

Now, we manufacture 3 kinds of roof ridge cap machines based on the market needs. They are Roof Tile Ridge Caps, Metal Roof Ridge Caps, V Shape Caps. And the V shape ridge caps sometimes used as a roof valley f lashings.

Ridge cap machine is composed by Strips Uncoiler, roof ridge cap roll former with drive system and shearing system. Punching and stepping system, PLC system, and hydraulic station.

Product Process of Ridge Cap Machine:

Brief Specifications of ridge cap machine:

- Uncoiler Capacity and Types: 3 Ton -5 Ton, Electric or Manual

- Suitable Coil Strips: 0.25-0.6mm thickness, 300*800 mm width. I.D 508-610mm, O.D: 1000mm

- Forming Rollers: 14-20, subject to final design

- Rollers Material: ASTM 1045, Quenched and tempered. Chromed 0.05mm thickness

- Shaft Material: ASTM 1045, hardness treatment

- Motor Power: 5.5KW

- Driven Method: Gear box or Chain& Gear

- Cutoff De Material: CR12, heat treatment

- Controlled System: Panasonic or Siemens PLC, Yaskawa Inverter, Omron Encoder, Omron Limit Switch

- Voltage: 308-440V, 50-60HZ, 3 Phase

Here is three ways to check the quality of finished products:

1. For the profile to see the length accuracy.

2. To check the stamping part at the same line or not.

3. To check the stamping part and rolling part if there is any damage part or not .