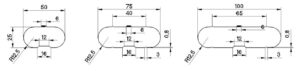

This oval pipe interlocked type roll forming machine is designed for producing oval shaped electric conduits or electric wiring ducting, is composed of a 3TON manual decoiler(also you can choose the hydraulic decoiler ), feeding unit, cooling system, roll forming system(Middle plate type or molding frame type), transmission system by chain or gearbox, cutting system, control system and run-out supporting rack. Take the following drawing profile for your reference:

Finished product pictures:

Oval tube interlocked type rolling forming machine Design:

Machine working process:

Decoiler—Feeding—Leveling—Roll Forming–Cutting–Product Table

| Decoiler | Expanding method: Manual expanded version. ID:450-500mmOD:1200MMMax loading:3 TonMax width:300mm |

| Leveling beach | Four rollers leveling beach to make sure material neat, clear and straight. |

| Rolling machine | 1.Roller station: 20 stations 2.Shaft material:45# steel Outer diameter:70mm3.Roller material: GCr15 quenching at 58 to 60 degree 4.Transport: Chain 5.Forming Speed: 0-8m/min 6.Motor:7.5kw 7.Machine :8.5mx0.8mx1.45m 8.Machine frame: 280 H beam9. Frame thickness: 20mm, middle plate frame9.Voltage:380v,50Hz,3 phase or csutomize |

| Flying cutting saw | Flying and tracking cutting saw, the cutting saw will adjust the cutting speed and location according to the main machine speed. By this method, the machine working speed will be same as the main machine accordingly. The cutting plate we take the best material for cutting it in high speed and beautiful cutting scare.

The material of blade: Cr12Mov, Hardening HRC 58-62℃ 3)Length Tolerance:3m±1.5mm 4) Flying cutting saw, can make sure the perfect shape after shearing. 5) Note: this type shearing syste could support three sizes of pipes. |

| PLC Control | 1.Screen: touch screen

2.PLC: Delta 3.Automatic-length measurement 4.Automatic-quantity measurement 5. Computer is used to control length and quantity. Machine will automatically cut to length and stop when required quantity is achieved Length inaccuracy can be amended easily |

| Hydraulic System | 1).Advanced hydraulic system from Taiwan

2). Power:3kw |

Questions about this oval tube interlocked type rolling forming machine?

Questions: if we have many sizes, can we make all sizes by one machine?

Answers: For the interlocked pipe, as the rolling forming is not so easy, so we do suggest that one machine to make one shape profiles. If we use fast change cattle, the price is also not lower but you can not do the production at the same time, so we do suggest that one machine one set profiles. By the following part, you can see, the locking part rollers are fixed according to the sizes. So if we change the rollers, that is quite hard, as there are lots of side rollers, vertical version and other type rollers.

Questions: How much cost of the machine?

Answers: Our rolling forming machine is designed according to the customer requirements, as to the decoiler you can use the manual one or hydraulic one. The main rolling machine we can use gearbox with molding frame type or economic type.

As to the shearing part, normally we will use the cold disk shearing like this to make sure the shearing will not change the tube shape.

We also make other type interlock tubes, if you need, please contact us at any time.