Metal wall panel rolling forming machine

Metal Wall Panel Roll Forming Machine is for producing wall panels automatically. The Machine can do the orders in batch fully automatically where you need input in the PLC. As to the length, you can control in the PLC, just one machine only can make for one type. You can adjust the input coil width and then the effective sheet width will be different.

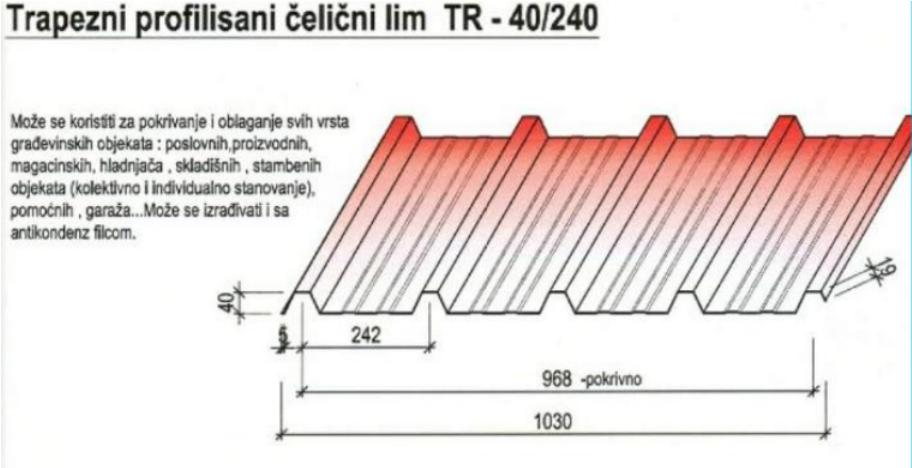

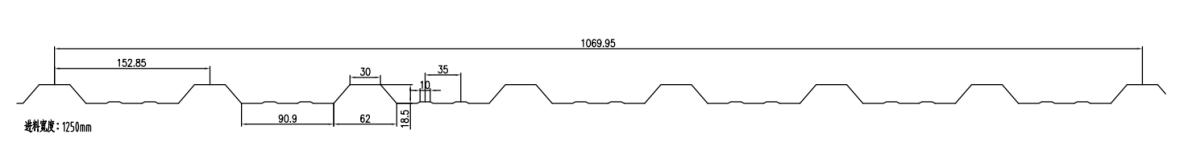

Here are some drawing profiles which quite popular in Europe for your reference:

Metal Wall Panel Roll Forming Machine of double layer type, you can also choose the single layer type:

What is the Metal Wall Panel?

As we know, traditional wall panels is made by brick, which is composed of clay-bearing soil, sand, and lime, or concrete materials. And nowadays, metal wall panel are widely used in Stadium, convention center, exhibition hall, railway station, high grade villa, airport, theater and many other architectural fields. Different with the roofing sheets, the wall panel sheet wave height is not so high. Metal Wall Panel(Roofing Sheets) is roll formed by common metal material with different sections. And also composite with heat insulation, water proof, sound absorption for a wide use. The material can be Galvanized steel, Pre-painted Galvanized Steel, Aluminum, Stainless Steel. The thickness is 0.2-0.8mm as usual.

As to the Metal Wall Panel Classification, there are several types likeInner wall panel, outer wall panel, decorative wall panel, Self-lock, horizontal, Vertical, But for the Function it is mainly for keeping warm, beauty, etc The Material use normally in the market use as aluminium alloy, PPGI, GI, Copper, etc. Zhongtuo Metal Wall Panels rolling forming machine can support all those material like,mini Orb Corrugated Sheets Roll Forming Machine. Clip Lock Roll Forming Machine, Decorative Wall Panel Roll Forming Machine, etc.

Metal Wall Panel Roll Forming Machine Components and Specifications.

Manual Uncoiler or hydraulic decoiler

Coil Inner Diameter: 460-520mm

Coil Outer Diameter: max 1300mm

Loading Weight: 5T Maximum

Manual Loosen and Tension, Passive Uncoiling.

Wall Panel Roll Forming Mill

Main Structure of the Machine: 350 H Steel, with 25mm steel plate welded

Roll Forming Stand Number:18 groups

Forming Speed: Approx. 15m/min

Diameter of Shaft: 80 mm

Material of Shaft: 45# steel with surface heat treatment

Material of Roller: ASTM 1045 steel with quenching treatment HRC58-60 and chroming of 0.05mm thickness

Transmission: Chain and the first and last 2 stands use gear to drive both upper and bottom shafts

MotorPower:7.5KW

All the driven part of wall sheet roll forming machine are covered with safety protection.

And in our website, we will share more information about other types wall panel rolling machine, please visit our website to know more.