Metal Roofing Sheet Roll Forming machine

Zhongtuo Roofing Sheet Roll forming machine is a professional building material manufacturing equipment that can help you easily produce high-quality, durable roofing sheets. This equipment uses advanced technology and materials to ensure that the roofing sheet produced have excellent performance and beautiful appearance.

First of all, Zhongtuo Roofing Sheet Roll forming machine is highly flexible and customizable. You can choose different forming molds to produce roofing sheets in different

shapes, sizes and colors according to your needs and budget. In addition, the equipment can be adjusted to different material and surface treatment requirements, ensuring that the roof tiles produced are of excellent quality and performance.

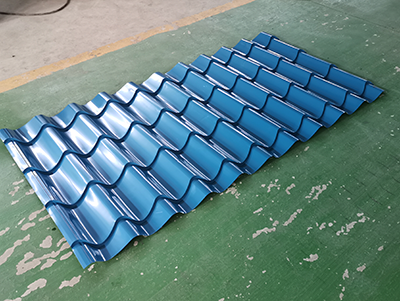

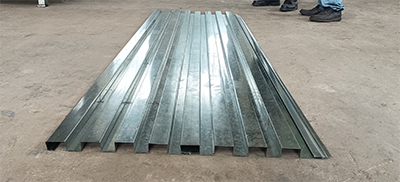

Here are some popular roofing sheet designs in the world:

R101 panel profile (Mexico)

IBR/Corrugated sheet profile(South Africa)

Box profile (UK)

5V/ PV4 panel profile(Chile)

C8/C44 panel profile (Russia)

Here are some main types of machines as followed:

- Corrugated roofing sheet roll forming machine

3. Glazed tile roll forming machine

4.Double layer roofing sheet roll forming machine

5. Standing seam panel roll forming machine

6.Wall cladding panel roll forming machine

Usually different customers have different production demand for the roofing sheet , so there are three common versions for different speed,and normally the speed is higher the strength is bigger, so it will need a stronger machine body and transmission method,here are the three main machine versions as followed:

- 10-12m/min, middle plate structure ,double chain drive ,the basic version of the machine

2. 20-25m/min, Independent cast iron archway structure, gearbox drive,very strong and higher speed than basic version machine

3. 35-40m/min,Independent cast iron archway structure, gearbox drive, servo track cutting , high speed and durable.

Main parameters of the roofing sheet roll forming machine

| 1 | Machine frame | 350mm H beam structure, with 18mm welded steel middle support plate. |

| 2 | Material of rollers | High grade 45# forged steel,Chromed treatment |

| 3 | Diameter of shafts | Φ80mm solid |

| 4 | Forming speed | 12-15m/min |

| 5 | Transmission way | By Chain |

| 6 | Main motor | 5.5KW |

| 7 | Cutting blade material | Gcr12 quenched treatment |

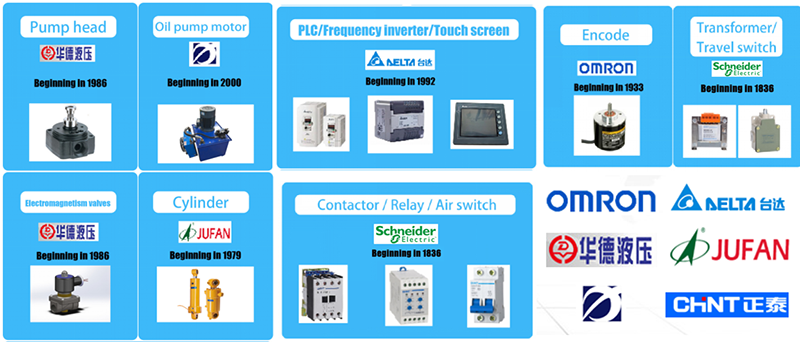

| 8 | Control type | By PLC |

| 9 | Hydraulic motor power | 5.5KW |

Zhongtuo roofing sheet roll forming machine uses advanced control systems and automation technology to make the production process more stable and efficient. The equipment can automatically complete multiple links such as uncoiling,roll forming, and stacking, greatly improving production efficiency and quality. At the same time, the equipment also has safety protection functions, which can effectively prevent accidents.

Our raw material and accessories source all use famous Chinese brand, which all have CE, ISO certificates,like bearing, screw/nuts, chainwheels ect,though these are small parts for the machine,we will ensure the quality to avoid any problems.

Siemens and Cangzhou Zhongtuo Roll Forming Machinery Co., Ltd. signed an intelligent manufacturing strategic cooperation agreement. The two parties will cooperate in programming, equipment performance optimization and other aspects based on Siemens automation and digital products and services to accelerate the digital transformation of roofing sheet roll forming machine manufacturing. Inject new momentum into the transformation and upgrading of the traditional machinery manufacturing industry.

中户屋面轧辊机也很容易维修.该设备结构紧凑,易于拆卸和清洗,确保长期稳定运行。此外,我们还提供专业的售后服务和技术支持,帮助您解决在使用设备时遇到的问题和困难。

简而言之,中投屋面板卷成型机是一种高效、灵活、耐用的建筑材料制造设备,可以帮助您轻松生产优质屋面板。如果您正在寻找一个可靠的屋面板制造解决方案,我们的屋面板轧辊机绝对值得您考虑。