Zhongtuo Metal rolling shutter door forming machine shutter slat making machine could be used to make the rolling shutters in batch fully automatically, especially this one, it can produce two types shutters at the same time, that means one machine for two profiles. This rolling shutter door speed can reach 25 meter per minute.

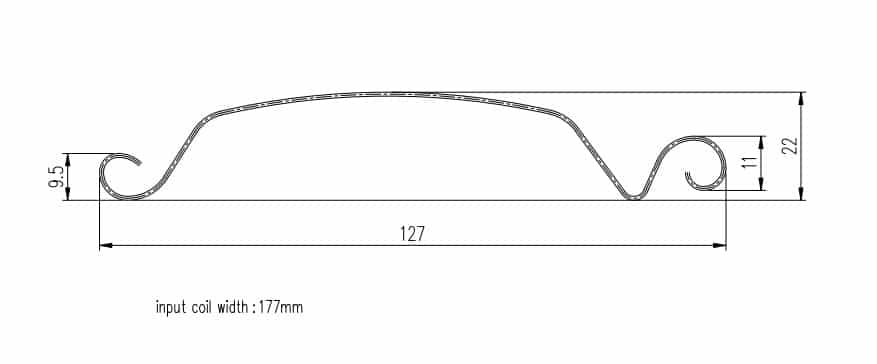

Here are popular drawing profiles of rolling shutter:

Here are some finished products for your reference:

Metal rolling shutter door forming machine shutter slat making machine parameters:

| Item | Name | Description |

| 1 | Machine structure | Iron Cast steel structure |

| 2 | Main power | 5.5KW |

| 3 | Forming stations | 16 stations |

| 4 | Way of drive | chain drive |

| 5 | Diameter of shaft | 60mm |

| 6 | Max rolling speed | 20-25m/min |

| 7 | Thickness | 0.5-1.2mm galvanized steel or prepainted sheet,G550Mpa |

| 8 | Material width | 150-300mm (as the profile drawing design) |

| 9 | Material of roller | Cr12 with quenched treatment |

| 10 | Material of blade mould | Cr12, quenched 58-62 |

| 11 | Way of cutting | hydraulic cutting(stop to cut) |

| 12 | Length cutting tolerance | +/-1.0mm |

| 13 | Hydraulic pressure | 16Mpa |

| 14 | Hydraulic power | 4kw |

| 15 | Control system | PLC control from Taiwan |

| 16 | Encoder | Omron |

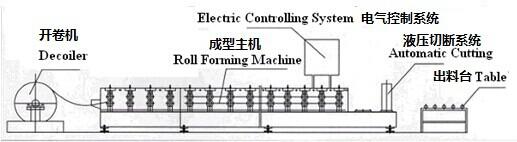

Work Flow of Metal rolling shutter door forming machine shutter slat making machine:

Decoiler—Feeding steel belt—punching holes if needed–roll forming–hydraulic cutting and punching head holes–hydraulic shearing–receive table

No.1 Feeding part of Metal rolling shutter door forming machine shutter slat making machine

Scientific design: Our feeding part adopts bearings on each side

Advantage: Protect PPGI & Help raw material go ahead smoothly

Bearing Brand: China Famous Harbin Brand

No.2 Shaping Part of Metal rolling shutter door forming machine shutter slat making machine

Scientific Design A: Cast Steel Roller Fixer

Advantage: Compared with middle plate, Cast steel can support more stable shaping

Scientific Design B: we put counter inside of rollers

Advantage :To ensure count accuracy

Scientific Design C:Control station installed on the machine

Advantage: 1.Save place.2.No need to connect the wire any more,easy to install

Scientific Design D:Loading hook installed in the machine

Advantage: Easy to load the machine,will not damage the body of machine

No.3 Hydraulic Cutting of Metal rolling shutter door forming machine shutter slat making machine

Scientific Design A: It adopts High quality steel pillars

Advantage: Considering that the thickness of the steel strip is generally thick,

the high quality steel column can withstand the pressure and reaction force better.

Therefore, the life of the machine will be extended and the cutting effect will be better.

Scientific Design B: It adopts powerful motor

Advantage:The motor power is enough to ensure that the cutting effect is neat.

Scientific Design C: Bigger fans

Advantage: The wind is strong to ensure that the hydraulic oil cools down quickly.

This design has a better cutting effect and a longer working time.

Scientific Design D:Oil pump installed inside of the machine

Advantage: Can save place for customers

No.4 Control system of Metal rolling shutter door forming machine shutter slat making machine

Scientific Design A: Control panel installed in the machine

Advantage: No need to connect the wire when the machine arrive at customers’ factory,easy to install

No.5 Rolling Shutter Door Machine Installation and Training

Technical team has more than 10 years of work experience

7 * 365 Online service

Welcome to our factory to communicate. We provide face-to-face technical guidance.

We also provide video tutorials and detailed instructions for use.