Metal Material Cut To Length Line Machine is a device used for processing metal sheets, mainly for unwinding, leveling, sizing, and cutting metal coils into flat sheets of the required length and stacking them. Metal Material Cut To Length Line Machine is suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel, and various metal materials after surface coating.

Production process:

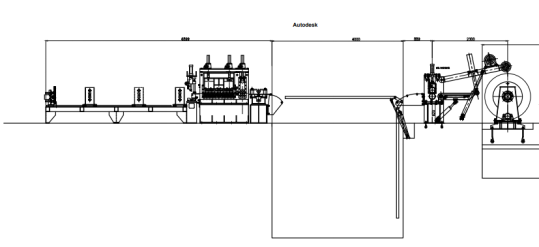

From right to left, they are Uncoiler + coil car—Press device with side guide device—straightener —Cutting machine—receivable table

Packing list of the Metal Material Cut To Length Line Machine:

| No | Name | Quantity |

| 1 | Hydraulic entry coil car | 1unit |

| 2 | Hydraulic De-coiler | 1unit |

| 3 | Press and pinch device | 1unit |

| 5 | Loop | 1unit |

| 6 | Side guide device | 1unit |

| 7 | Straightener machine | 1unit |

| 8 | Cutter | 1unit |

| 9 | Stacker | 1unit |

| 10 | Hydraulic system | 1 sets |

| 11 | Electrical control system | 1 sets |

Metal Material Cut To Length Line Machine have the following advantages:

- High degree of automation: simple and reliable operation, high precision in fixed length, high flatness of sheet metal, and neat stacking.

- Wide applicability: Suitable for industries such as transformers, motors, home appliances, automobiles, building materials, packaging, etc.

Main parameters for you reference:

1. Input : 1600mm

2. Thickness : 5-3.0mm

3. Rollers : 6 up 7 down, 2 input

4. Shaft : Φ110mm

5. Wall panel : 25mm, A3 400H steel frame

6. Drive motor Power : 15kw

7. Speed : 0-15m/minute

8. Hydraulic power: 7.5 kw

9. Driven : gear box

10. Slitting and shearing blade: Cr12

11. Slitting quantity : 6 strips maximum

12. Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase (this is can depend on customer request)