Metal Door Frame Forming Machine

Metal Door Frame Forming Machine is used for rolling forming metal door or window frames. We can design the punching according to your needs. The advantage of this machine is the surface will be very smooth and beautiful without any scratch on surface, after rolling formed by this roll forming machine. Projects Application This Door frame Forming Machine is high strength and durable, so the finished products have good quality and great strength, providing more security.

Metal materials for door frame or window frame and parts that are rolled, extruded, stamped or machined to make industrial and civil building doors and windows. Compared with wooden doors and windows, metal doors and windows have less deformation, good durability, less shading, but greater thermal conductivity. Bu this artile, we only shows the metal rolling forming machine of the door frame.

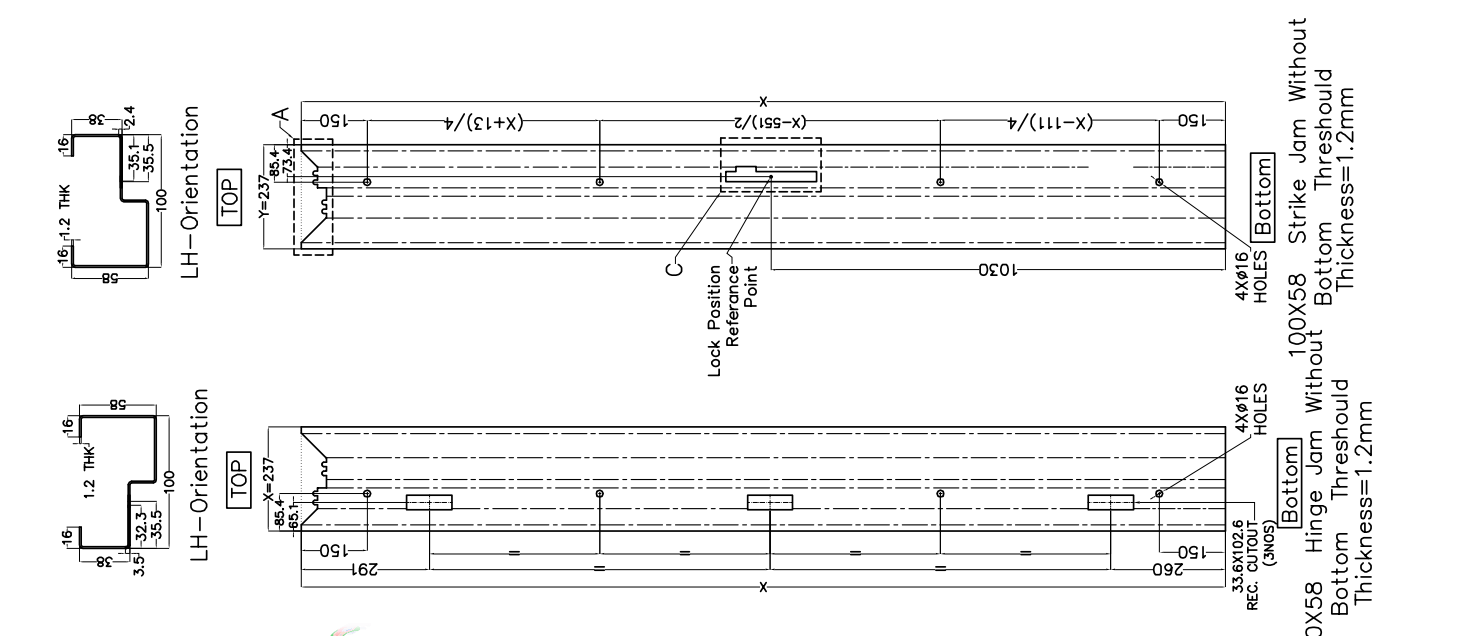

Here are some drawing profile of door frame for your reference:

Window frame and door frame installation showing:

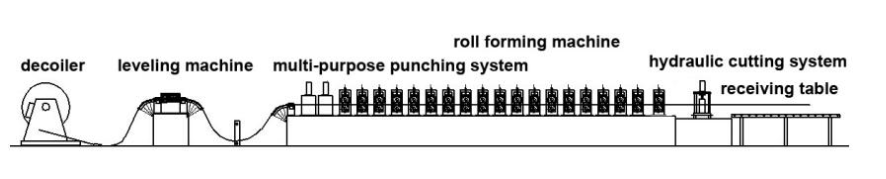

Metal door frame rolling forming machine working flow:

3T hydraulic decoiler→leveling machine→guiding platform→auto multi-purpose punching system→main roll forming machine→hydraulic cutting system→2m output table, two 11kw electric motors, hydraulic station with 5.5kw electric motor, PLC control system

Metal door frame rolling forming machine basic parameters for your reference:

1) Processing material: steel strip, coil tensile strength 280Mpa-550Mpa

2) Material thickness: 1.5-2.0mm

3) Formed size: as per profile drawing above

4) Main motor power: 11kw+11kw

5) Pump power: 5.5kw

6) Productivity: 4-12m/min

7) Roller stations: 20-22 steps

8) Roller material: GCr15 steel with vacuum heat treatment HRC57°-60°

9) Active shaft material: 40Cr

10) Shaft diameter: Ф70mm

11) Cutting system: hydraulic mould cutting type, automatic cut to any length you need

12) Cutting blade material: SKD11

13) Punching system: auto multi-purpse punching device

14) Punching mould material: SKD11

15) Machine construction: as per machine photos

16) Transmission type: double chains

17) Control system: Taiwan Delta PLC computer control system with inveter

18) Power supply: 380V, 3 Phase, 50Hz(or as per your request)

19) Machine dimensions: about 8.5*1.6*1.2m

20) Machine weight: about 7700kg

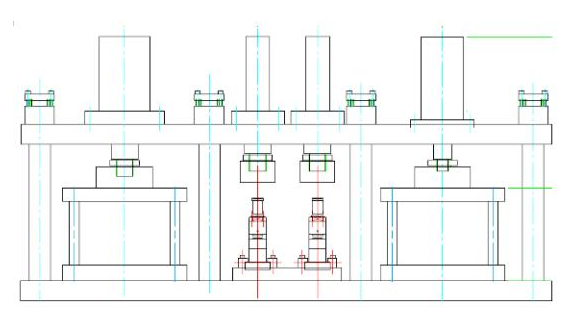

As to the punching part, we design like this:

And for this machine, if you want to know more information, please contact us at any time.

Ralted products:

Metal door panel machine.

Window frame machine.