The Kr18 standing seam roll forming machine is a remarkable device that functions with high – precision rollers. These rollers rotate precisely and work together to gradually transform the metal sheets into standing seams. It works stably and efficiently, because of its excellent mechanical structure and control system. Additionally, it can be flexibly adjusted to adapt to different production requirements, and it guarantees the high – quality formation of standing seams, which are widely used in roofing and wall panel construction.

The machine:

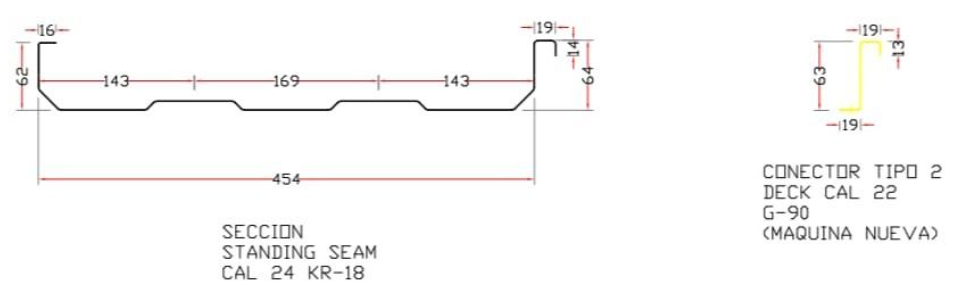

Customer drawing

Basic information of machine:

| Power | 5.5KW+3.0KW |

| Size | 5.8m×1.2m×1.65m |

| Weight | 3 tons |

| Material of rollers | 45#CNC manufactures with chrome quenching |

| Drive | Chain and gear |

| Steps of rollers | 9 rows |

| Material of cutting blade | Cr12 1 Mov |

| Electrical Standard | 220V/60HZ/3PH |

| Forming Speed | 15m/min |

| Control System | PLC (Omron) |

| Uncoiler Capacity | 6 tons |

2.Roll Details

Rollers and shafts. The material is 45# steel , quenched and polished by CNC machine. We connected rollers and shafts with no screws, in this way, the loose connection between the roll and the shaft due to the loose screw will not lead to the change of plate shape.

3.Spare Part of Kr18 standing seam machine

Recommend related machine:

After-sales service

1. Warranty: One year ,and we will provide the technical support for the whole life.some spare parts are available.

2. Training: Due to the epidemic, it is not possible to send technician abroad for training, so we will arrange online video training.

3.The advantage of my factory: we have a team of skilled engineers and one group for after-sale service