Indonesia popular glazed tile roofing sheet machine is designed to make the glazed tile in batch fully automatically which is quite popular in Indonesia. The machine is designed to make the glazed tile in batch fully automatically which is quite popular in Indonesia. The step tile designs are huge in the market, we can not list all of them here. Here we take the one which is quite popular in Indonesia. If you are interested in our machines, please click here to contact us at any time. We are waiting for you!

Indonesia popular glazed tile roofing sheet machine working videos for your reference:

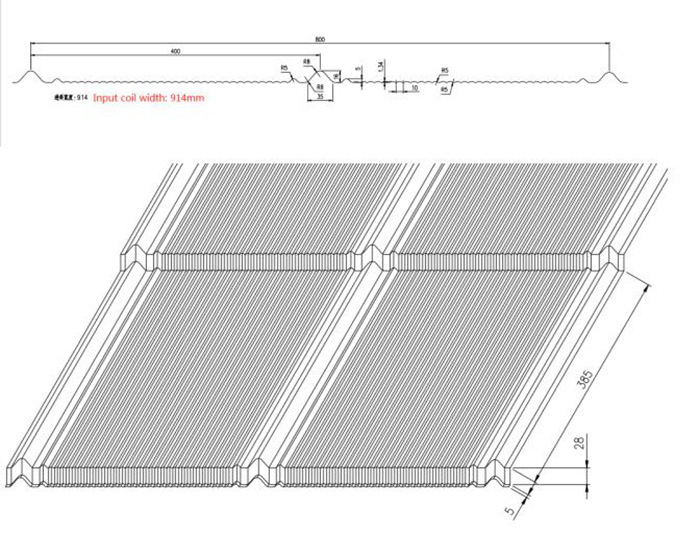

Here is the popular drawing profile for your reference:

Finished Indonesia popular glazed tile for your reference:

Here is a picture of standard Indonesia popular glazed tile roofing sheet machine for your reference:

Why our glazed tile roofing sheet machine can benefit you?

a). Decoiler

If you need to use the hydraulic automatic one we can supply you. If you want to save the cost, we can supply the 5 Ton manual one using this type quality. It is designed by a big wheel. with manual brake, so operate more easily.

b). Guide feeding device with leveling and cutting

By the cutter, you can remove the untidy start or cut it at any length.

- With several support rollers, to feed the material more smoothly

- Equipped with 2 plastic bands in the middle of the platform and two pinch plates to feed the material, prevent the material surface from being damaged, and feed the material more easily and quickly.With hand wheels to adjust the feeding size, more conveniently.

c). Rollers:

Advantage: For all of our rollers, spacers and shafts, we all mark numbers on it, it’s very convenient for you to maintenance the machine in the future. There is ball bearings inside the rollers, to make all the rollers run at same speed when machine is run. Because the rollers inside with ball bearings, our rollers is bigger than others, so work speed is faster. All rollers and spacers, we do 3mm thickness chrome coating, to increase hardness and anti-rust. Some factories maybe use 1-2mm chrome coating.

d). Hydraulic oil pump station

We designed with : with air-cooling system to prolong the service life.

Include a set of hydraulic tank, a set of hydraulic oil pump, four hydraulic pipes. And two sets of electromagnetism valves

Driving method : By pillar type Cylinder

Hydraulic motor power 4.5kw;

Cutter material: GB-Cr12

Cutting length tolerance : ±1mm/3m

Cutting feature : Steady and safe working condition

e). PLC control part

we can design with either portable type or cabinet type. It can supports more languages type and around 12 batches of order setting.