IBR roof sheet making machine is very popular in South Africa because its finished products are widely used in commercial, industrial and residential buildings. What’s more, the apprerance is beautiful. IBR is abbreved from “Inverted Box Rib”. The IBR roof making machine can produce IBR roof sheet in a size of 686mm and 890mm. ZhongTuo can also produce customized machines for your personal requirements, such as corrugated roof sheet making machine, glazed roof sheet making machine and double layer roof sheet making machine . If your are interested in our other different kinds of machines, please click here to contact us without hestation!

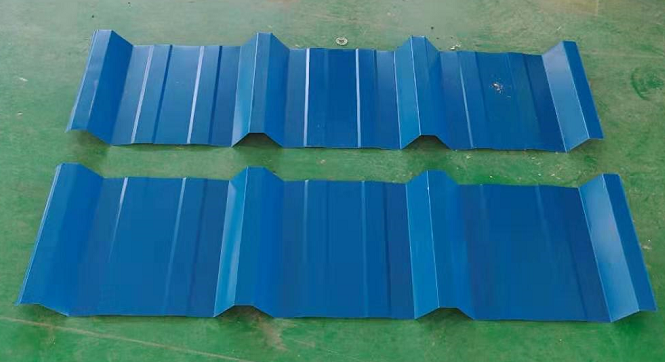

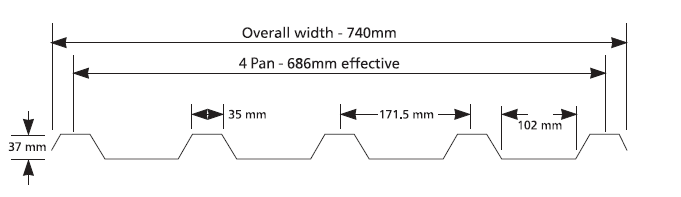

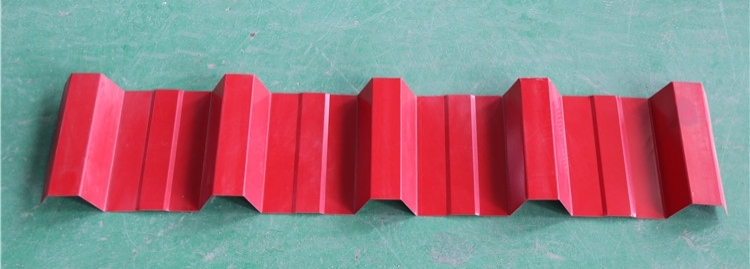

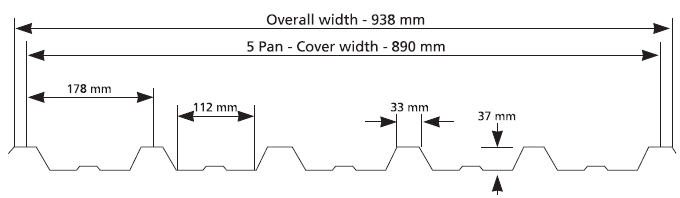

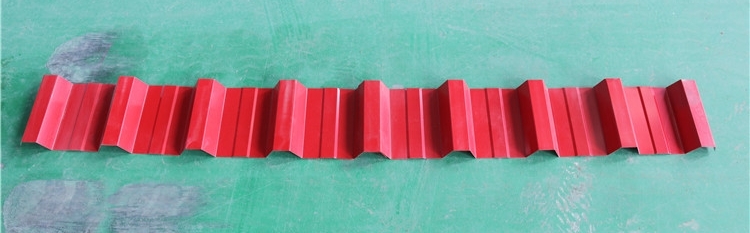

There are drawing profiles of IBR roof sheets and finished products show for your reference:

Drawing profile of 686-IBR-roof-sheet:

Drawing profile of 890-IBR-roof-sheet:

Material information of IBR roof sheets:

- Coil Material: GI coils, PPGI coils(as usual, our customers use full hard material, G550)

- Coil Thickness: 0.3-0.8mm

- Feeding Width: 925mm, 1219mm

- Effective width: 686mm, 890mm

Technical specifications of 686 IBR for example sheet roll forming machine:

- Uncoiler: Manual Uncoileror you can choose hydraulic decoiler

- Inner diameter: 508mm

- Outer diameter: 1250mm.

- Loading weight: 5TONs or 10 Ton

- Forming speed: 12m/min.to 50 m/min

- Forming steps: 16 stations

- Material of Shafts: 45# high-quality steel

- Diameter of Shafts: 70mm

- Material of Roller: high quality 45#steel coated with hard chrome 0.05mm.

- Thickness of Siding Plate:25mm

- Transmission: chains-sprocketsor gearbox

- Motor Power:15 KW

- Material of cutting blade: Cr12 with quenched treatment 60-62

- Hydraulic Power: 4 KW

- Panasonic PLC Control system,touch screen, frequency converter

- Voltage 380V/50HZ/3phaseor customize

The features of the machine are as the following:

1 More efficient and accurate execution of production orders;

2. High equipment reliability;

3. Little waste of materials and energy;

4. High productivity;

5. High quality materials, get a longer service life;

6. All parts of the machine are processed with precision, and the surface of the roll is chromeplated to ensure that customers can get qualified products at the same time, it can avoid the scratch of the color steel surface paint, and increase the service life of the roll;

7. Customized coil processing solutions to solve all aspects of technical problems.

The following part is about the details of the IBR machine:

- For the gear it is important for the machine we use Chinese famous brand HRB.

- For the leveling part, we will use two layer and handrail adjustment.

- For the roller we use the carefully polishing to make sure it willnot damge the surface of raw material

The main parts of the IBR roof panel roll forming machine is composed by the following elements:

- Manual Uncoiler;

- Feeding Guider;

- Roll forming machine;

- Hydraulic Cutting system;

- PLC Control System;

- Runout Table