In the field of construction, undoubtedly, the quality and appearance of roof tiles hold a crucial position in determining the aesthetics and durability of the entire building. The advent of the corrugated roof sheet machine has truly brought a remarkable breakthrough and significant change to the production of roof tiles. You see, the corrugated roof sheet machine is an advanced piece of equipment that is specifically designed to produce arc-shaped roof tiles. It cleverly adopts modern technology and techniques to efficiently and accurately manufacture various specifications and styles of arc roof tiles, thereby meeting different architectural styles and needs. This innovative machine not only streamlines the production process but also ensures the highest quality output. It’s no wonder that it has become an essential tool in the construction industry.

The High-speed corrugated roof sheet production line is truly remarkable. For starters, it features a reliable operation. You see, the machine structure is an arch structure, which not only makes it more stable but also ensures a long service life. Moreover, it has a high transmission efficiency. The gear box’s transmission efficiency is relatively high, and the transmission accuracy is also on a high level. This production line is capable of high-speed production up to 45m/min, and it makes high-quality corrugated roof sheets. Additionally, it comes with a servo cutting system. This system uses a no-stop cutting way, which guarantees high-speed cutting. Last but not least, it has an automatic transport and stacker system. This system matches the high-speed production line perfectly. There is no need for manual operation, thus saving labor.

The technical specifications of a high-speed trapezoidal tile roll forming machine:

1.The 1.8 tons hydraulic Uncoiler is an essential component of the production setup. Firstly, it has a capacity of 8 tons. The coil width can be up to a maximum of 1250mm, as per customer’s request. In terms of working type, it is a passive type with a brake to stop the uncoiler. Additionally, it features hydraulic coil core expansion. Moreover, it has a 4 support arms design. This design supports the coil and prevents creases when uncoiling. It also makes sure a high-speed feeding of the material. Furthermore, the car can move levelly and vertically, which is extremely convenient for putting the steel coils into the uncoiler.

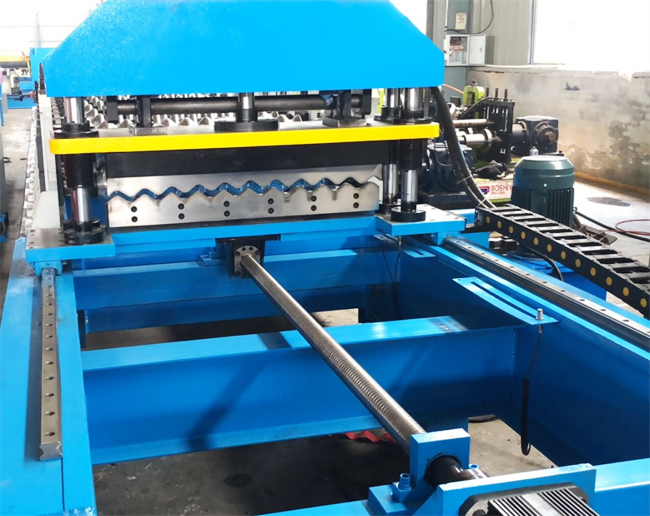

2.The Roll forming machine is truly impressive. For one thing, it has an arch frame with 40 mm thickness, which is connected with the body by bolts and nuts. Additionally, it features 19 roller stations. The roller material is 45#, and it undergoes finishing after quenching heat treatment. This ensures that high rotation does not produce heat, guaranteeing hardness and a long service life. Moreover, the roller shaft is made of 45# material and undergoes tempering treatment. This helps prevent deformation and improve hardness. The diameter of the roller shaft is 80 mm. As for the transmission type, it is by gearbox. Furthermore, the speed of the machine can range from 0 to 40 m/min.

3.The Hydraulic servo cutting system is highly efficient and reliable. Firstly, it features automatic hydraulic cutting controlled by PLC. Moreover, it has a no-stop cutting design, which is achieved by moving with the servo motor. Additionally, the material of the cutting blade is GCr12Mov. This ensures a steady and safe working condition and low sounds.

4.The Automatic stacker allows free unloading of each cut profile and automatic placement on the stack of previously made products. The top sheet won’t damage the sheet below, and the profile of the lower sheet matches that of the top sheet. It features a roller design suitable for very long roof sheets with no scratch on the surface.