As the most commonly used new building material, the market demand for drywall system light steel keels is expanding day by day. The huge market demand also puts higher requirements on production equipment. In the process of colliding with the development trend of Industry 4.0, our company’s technical research and development team has developed more efficient and intelligent partition drywall C U channel keel production equipment.

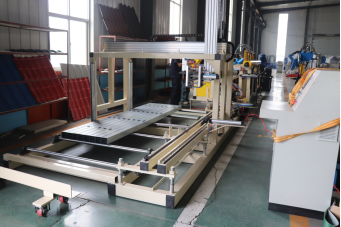

Our company can provide partition keel machines with intelligent exchanging, remote monitoring, automatic collecting, and convenient operating.

In terms of intelligent exchanging, our company’s equipment uses servo motors to adjust the frame of the entire machine, and cooperates with the control of the PLC industrial computer system to realize the automatic change of the required product size. Abandoning the adjustment method of adjusting the spacer to exchange the size, the PLC control system sends a exchanging instruction to the servo motor. The servo motor receives the signal and drives the screw mechanism to perform a horizontal movement on the machine frame. Combined with the servo motor’s precise control of movement, it realizes automatic change of product size while ensuring product accuracy.

A smarter choice for the drywall C U profile roll forming machines. Our electronic control system can realize functions such as remote data transmission and interface synchronization, and display, input, and modify the machine’s order settings, operating status, parameter settings, and other functions through signal transmission methods such as WIFI and data networks.

In order to realize the intelligentization and automation of machinery and equipment, our equipment can also be equipped with fully automatic palletizers, fully automatic balers, etc. After the C-type partition keel/U-type partition keel is completed, the automatic stacker can realize automatic material turning, automatic closing, automatic conveying, automatic grabbing and stacking by the manipulator; the fully automatic packer can perform small package baling, large package baling and other functions. After setting the baling parameters, the product sends a signal to the control system through the sensor and feeds back to the baler for baling. The whole line process is automatically executed, saving labor costs and improving production efficienc