New Customized Heavy Duty Metal Scaffolding Plank/Catwalk Roll Forming Machine is designed to make many sizes of scaffold plank decking panels in batch and fully automatic. The whole production line is controlled by PLC, through PLC you can control metal scaffold plank decking working speed, production quantity and also the length. Scaffold Metal Decks and Steel Planks are made in Galvanized and Painted with Plain Ends and Hook-on for Scaffolding System, Pipe and Fitting Scaffolding, the material thickness is from 0.8 to 2.0mm.

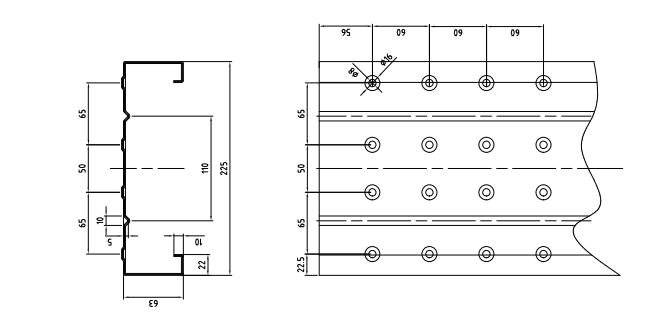

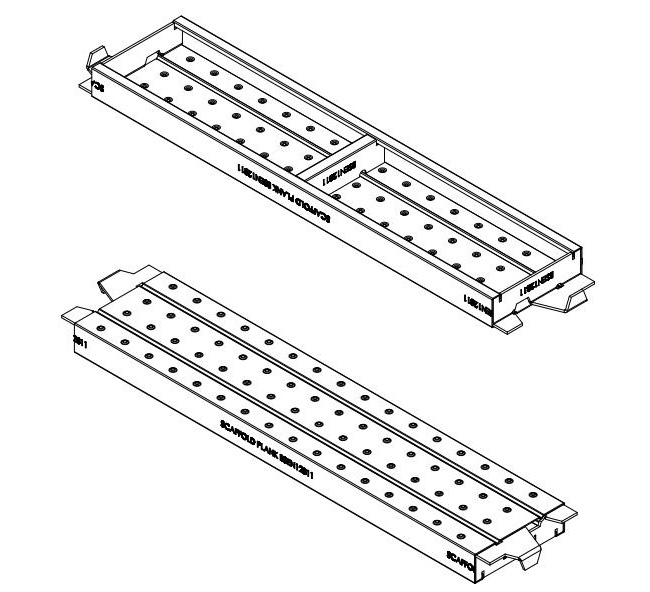

In the market, there are lots of metal decking types, take the following profiles for example:

With hook effect:

New Customise Heavy Duty Metal Scaffolding Plank/Catwalk Roll Forming Machine Components:

| No. | Name | Type | QTY | Power(KW) | Mark |

| 1 | Decoiler | 5THydraulic decoiler | 1set | ||

| 2 | Servo feeding

&leveling |

with independent control device | 1set | 7.5KW | Pneumatic |

| 3 | Punch machine | Yangli 80TONS | 1SET | ||

| 4 | Punch dies | 1SET | SKD11

|

design as holes | |

| 5 | Main forming machine | memorial arch type,gear box drive | 1SET | 22KW | |

| 6 | pneumatic circuit

|

0.5m2/min;0.7Mpa

|

1SET

|

||

| 8 | Hydraulic cutting | 1SET | 5.5KW | ||

| 9 | Control system | PLC CONTROL | 1SET | ||

| 10 | Runout table | 3M | 1SET |

|

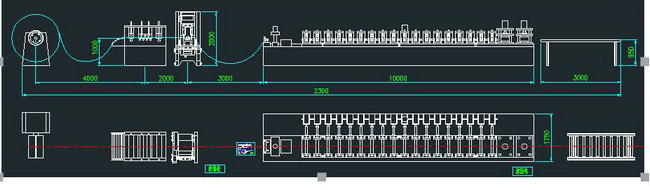

Metal Scaffolding Plank/Catwalk Roll Forming Machine Work Flow:

Metal Scaffolding Plank/Catwalk Roll Forming Machine parts:

- 5ton Hydraulic Decoiler

Hydraulic tightening, built-in motor drag.

Ø Bearing capacity: <5t

Ø Applicable material roll inner diameter: φ508mm

- Metal Scaffolding Plank/Catwalk Roll Forming Machine Punch Machin

Adopt more advanced straight punching method to improve punching efficiency.

When the plate thickness changes, first adjust the center distance between the upper and lower rollers of the roller punch roller, and then adjust the bridge gear through the adjustment device.

- Metal Scaffolding Plank/Catwalk Roll Forming Machine Punch Machine Main Forming Machine

Supported coil width: ≤500 mm

Material thickness: 1.2mm-2.0 mm

Supported mateiral: S275 GI

Machine working speed: 5~10 m/min

Main power: 22kw

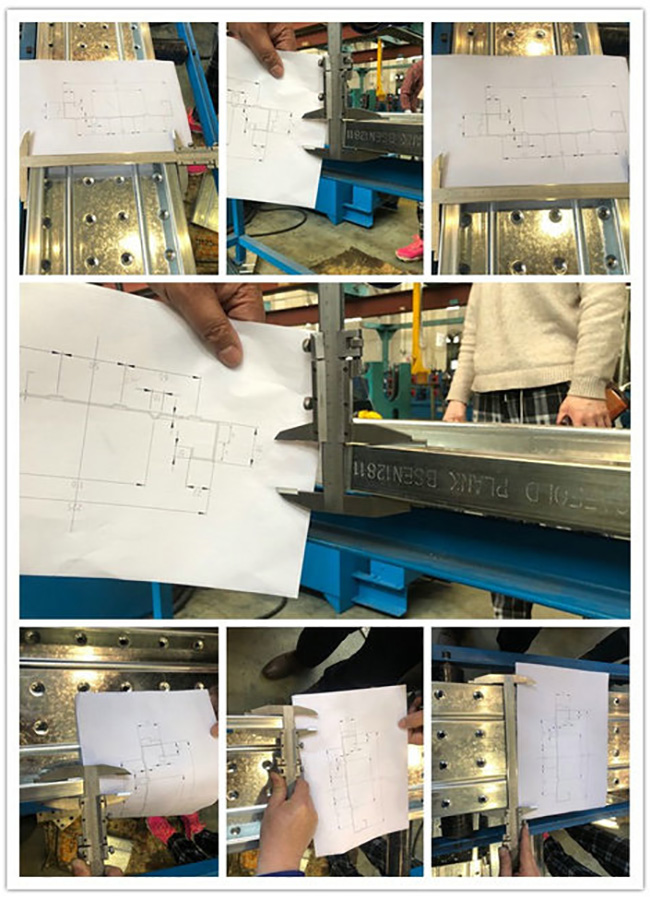

Check about our precision: