Gearboxes can achieve acceleration or deceleration conversion by adjusting the size and meshing relationship of gears. For Glazed Tile Roll Forming Machine for gearbox transmission, this means that the operating speed of the machine can be adjusted according to production needs to improve production efficiency or adapt to different working conditions.

Machine introduction:

1.One machine can produce glazed sheet.

2.One machine can use 1250mm width coil.

3.The finished product is absolutely flat after cut.

4.The voltage of this machine is 380V-50HZ-3P.

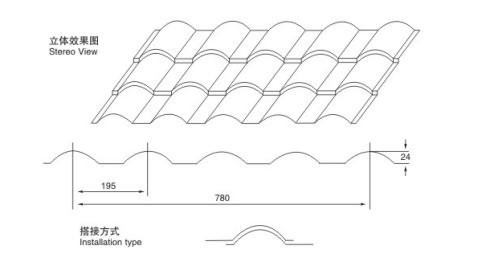

The profile drawing:

Application areas:

The glazed tiles produced by the Glazed Tile Roll Forming Machine for gearbox transmission have the characteristics of beautiful appearance, antique elegance, exquisite and unique shape, and are suitable for garden style factories, tourist scenic areas, pavilions, hotels, villas, exhibition halls, resorts, and homes, as well as outdoor decoration.

The technical specifications of the Glazed Tile Roll Forming Machine for gearbox transmission:

| Item | Name | Specifications |

| 1 | Raw material | colored steel plate, galvanized plate, or aluminum plate |

| 2 | Raw material thickness | 0.3—0.8mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 20stations |

| 6 | Roller material | 45# steel, surface hard chromium plating. |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By Gearbox |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The main features of theGlazed Tile Roll Forming Machine for gearbox transmission include the following aspects:

1.Multifunctionality:

The Glazed Tile Roll Forming Machine for gearbox transmission has multiple functions. By selecting different machine heads, different varieties and specifications of bricks and tiles can be produced, which allows users to flexibly operate according to market demand and avoid market risks of a single product.

2.Energy saving and efficient:

This device uses less power, which can save energy consumption and help reduce production costs. In addition, the control system of the Glazed Tile Roll Forming Machine for gearbox transmission is easy to operate, and there is no need to reverse first during the production process. It can directly move forward, press, and cut, with a cutting accuracy of less than 0.1mm, meeting the process requirements.