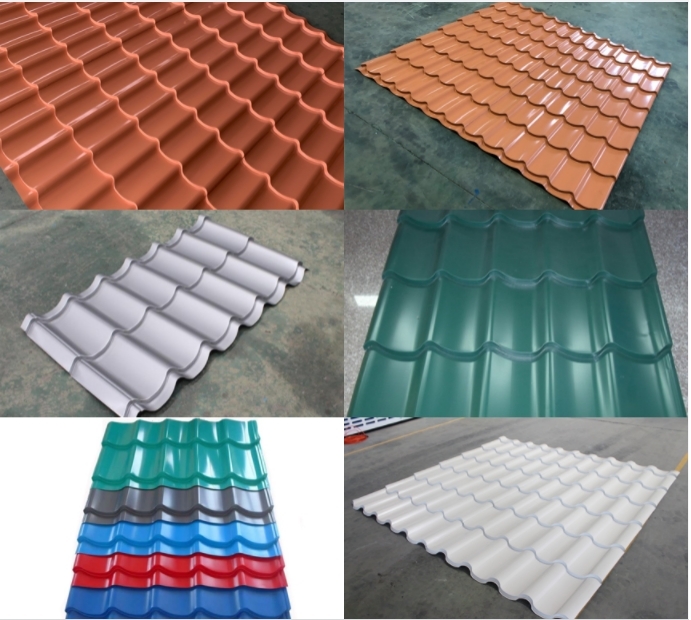

The roof tiles made by our glazed roof tile making machine are in different colors and have beautiful appearance. These finished products are widely used in gardens, factories, resorts, hotels, exhibition halls and modern villas. ZhongTuo company can also design and manufacture other kinds of glazed roof tile making machines, such as 1100 tile water ripper glazed tile steel making roll forming machine, which is popular in Europe. The glazed roof panel forming machines that enjoy high popularity in Italy are available in our cmpany. Here let me show you a video of the glazed roof tile making machine. It is a high-speed machine which can work 7 to 11-meter per minute.

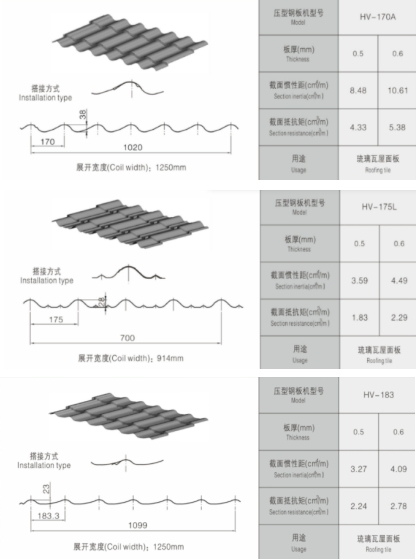

Glazed roof tiles represent the elegant style of traditional decoration and suit every architectural design. And these finished products are much more convenient campared with other types of roof panels. It take shorter time to install these glazed roof tiles. Our machine can make glazed tile roofs through 0.3-0.8mm thickness raw metrials. Here are the drawing profiles and finished products show for your reference. If you want differnt sizes of glazed roof tiles, we can also design the accordingly machine for you to meet your needs. So cantact us and tell us what you require, we promise that you will be fully satisfied with our machines.

Applications of finished products:

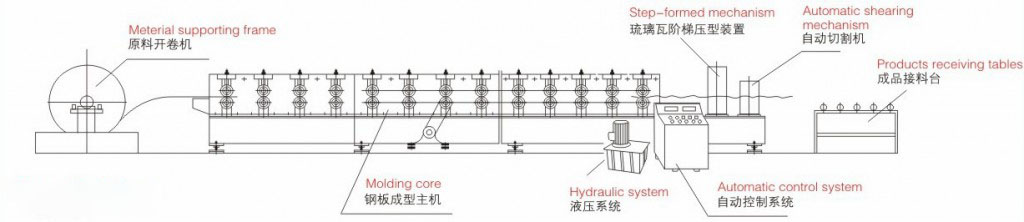

Working flow of the glazed roof tile making machine:

Tile profile unit

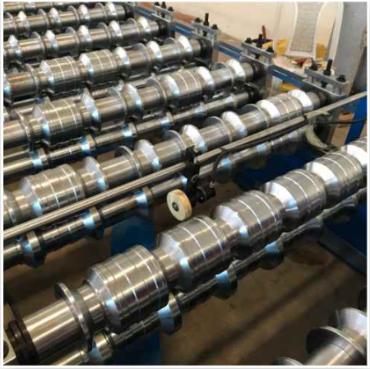

Extra refined profile rollers

Individual connecting wall

Hydraulic back cutter

360° degree remote control

Zigzag machine chasis

Glazed roofing tile roll forming machine specification:

| Product | glazed roof tile making machine |

| A.General details | |

| Suitable Material | HRB60 or equivalent(PPGI/PPGL/GI/GL) |

| Materials thickness | 0.3mm-0.8mm |

| Dimension | About 6.5*1.5*1.5m(L*W*H) , as per the drawing |

| Length of the Sheet |

can set the length according to your infact need. It is controlled by PLC which can ensure the accuracy of ±1mm. |

| Cutting | Automatically stop and cutting when it comes to the set length. |

| B.Components Details | |

| Roller Material | High grade 45# steel. Hard chrome plating, 0.05mm. |

| Main Frame | 350# steel. More stable and no shaking. |

| Middle Plate | 16mm. We use thicker plates to ensure stability of our products. |

| Forming Steps | 14steps, according to the drawing. |

| Shaft Material | Φ70 mm, high grade 45# steel. Treating process: tempering- finish turning, high rigidity, hard to deform. |

| Cutting Blade Material |

Cr12, hardness HRC60-62. Treating process: heat treatment- plane abrasion- wire electrode cutting. |

| C.Electric Components | |

| Suitable Power | 380V, 50 Hz, 3 phase or according to your need. |

| Screen | 7 inch touch screen, easy to operate.Brand Delta or based on your need |

| PLC | Delta Brand (Or Panasonic /Siemens ) Well-adapted to various conditions, such as moisture, electromagnetic disturbance. |

| Frequency Converter | delta ; It has the advantage of slowing down before cutting, to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

| Length Measurement Device |

Omron, made in Japan. It features with high accuracy and stability. |