Description of The Galvazied Steel Door Frame Making Machine

The galvazied steel door frame making machine is designed to produce door frames batchfully. ZhongTuo has manufactured this kind of machines for years, therefore we embrace rich experience and have the confidance to offer you with high-quality machines. The shutter door rollforming line in our company includes door frame rollforming line , door panel rollforming line , garage door rollforming line , shutter door slat roll forming line , shutter door U side channel rollforming line. If you are interested in our company and want to buy customized machines , then do not hesitate to contact us! Here is video of fully automatic door frame rolling forming machine for your reference.

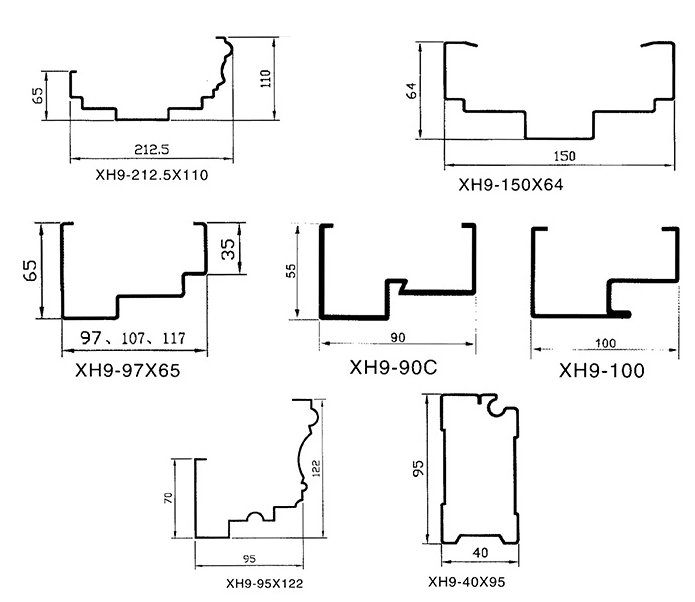

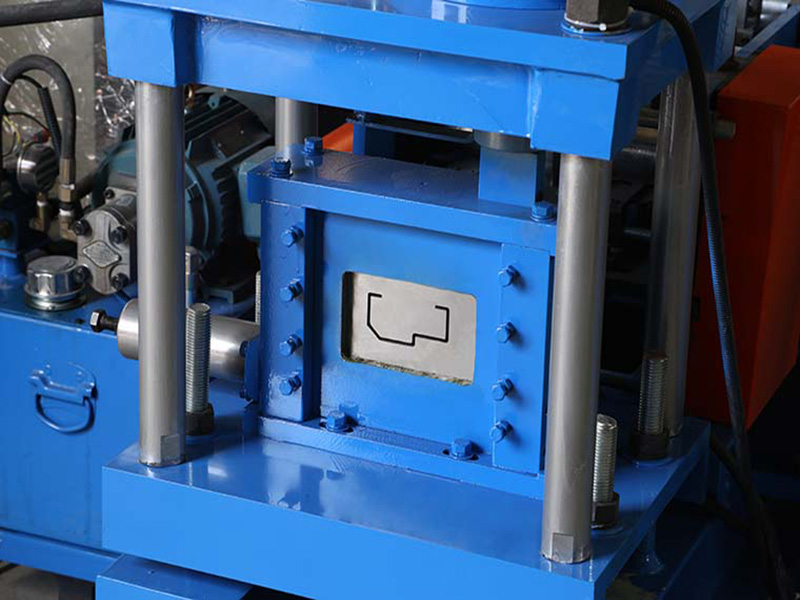

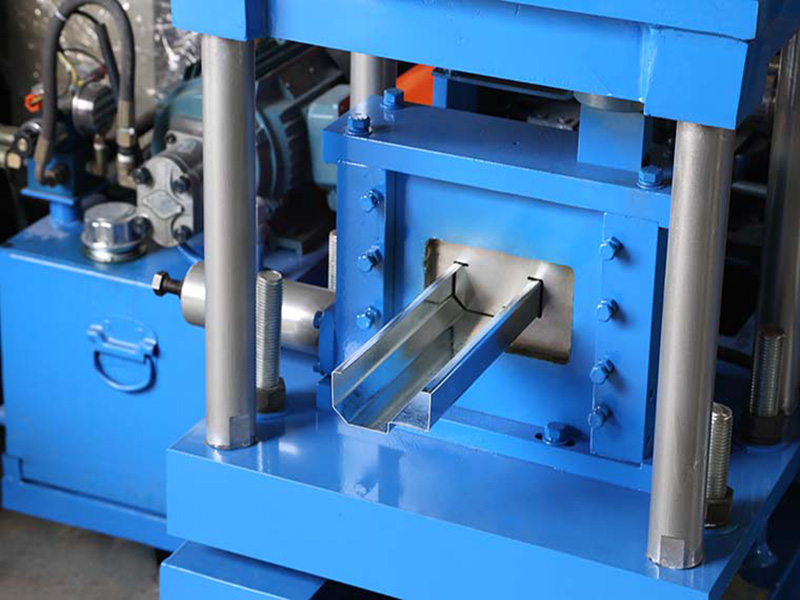

Profile Drawings of Door Frames and the Finished Products

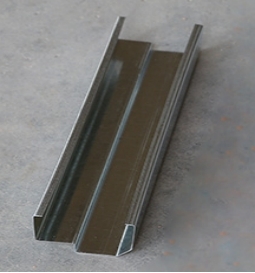

Door frames produced by our machine is made from galvanized steel or cold roll steel. The raw material thickness is from 0.8-1.5mm. Therefore, they are more corrosion-resistant than wooden door frames and enjoy longer life.

Applications of The Galvazied Steel Door Frame Making Machine

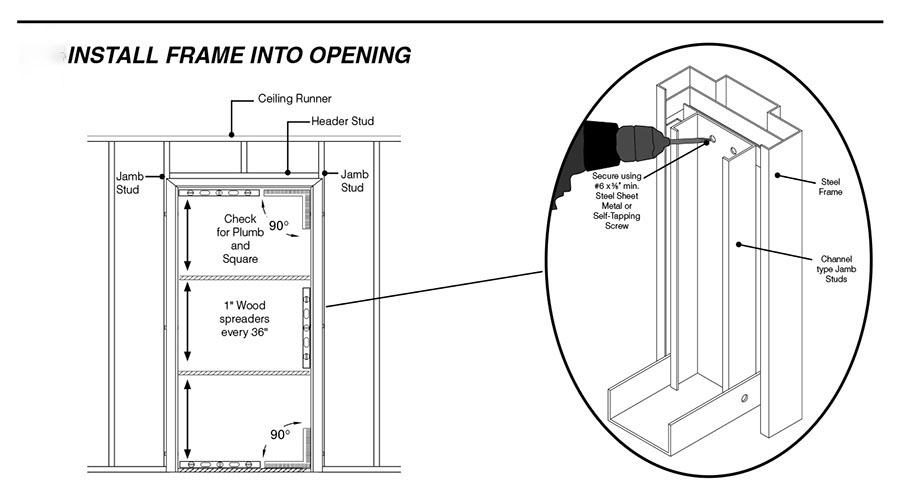

How to install door frame:

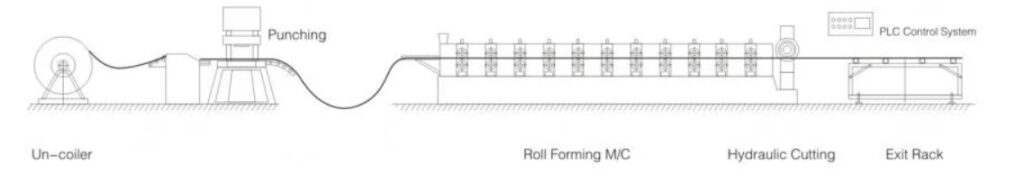

Working Flow of The Galvazied Steel Door Frame Making Machine

:

Features and Advantages of the Galvanized Steel Door Frame Making Machine:

- The machine is equipped with PLC computer control and is easy to operate.

- The hydraulic system is made from famous brand and it enjoys long life.

- The appearance of the machine is beautiful.

- We offer you the best after-sales services.

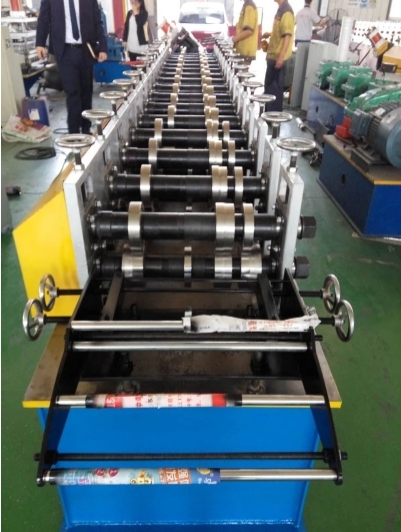

Main Components of The Galvazied Steel Door Frame Making Machine

Manual Decoiler(Double Coils): one set

Un-powered, Manually control steel coil inner bore shrinkage and stop Max Feeding width: 500mm,coil ID range 508mm±30mm Capacity: Max. 3 Ton

Feed Guide Device:

Main Machine Body

Body frame made from H400 type steel by welding

Side wall thickness: Q235 t18mm

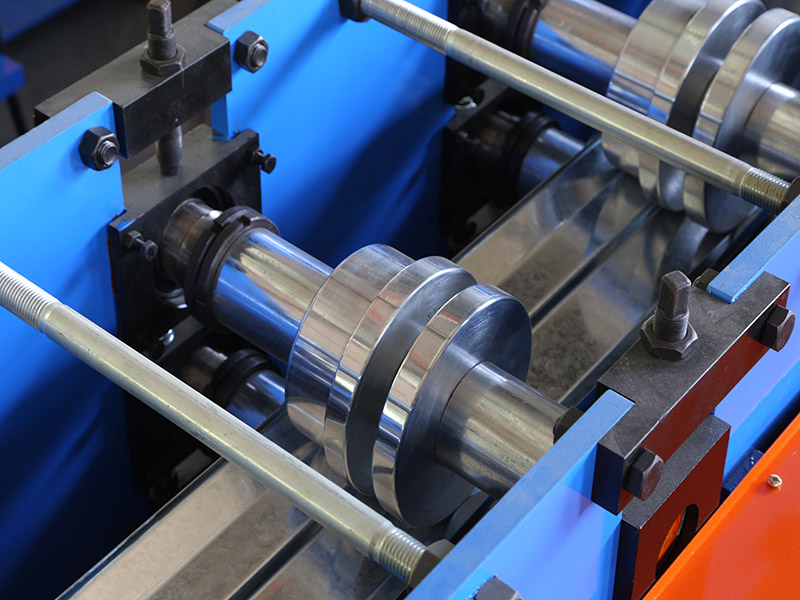

Rollers manufactured from 40Cr Steel,CNC lathes,Heat Treatment,hard Chrome Coated,with thickness 0.04mm,surface with mirror treatment(for longer life and anti-rust)

Shafts Diameter=ф75mm,precision machined

Gear/Sprocket driving,about 18-step to form

Main Motor(Polaroid brand)=11KW,Frequency speed control

Real forming speed 15-18m/min(Not include cutting time)

Post Hydraulic Cutting Device

Post to cut, stop to cutting,Two pieces type of cutting blade design, no blanking

Hydraulic motor: 3KW

Cutting tool material: Cr12MoV(= SKD11 with at least one million times of cutting life), Heat treatment to HRC58-62 degree

The cutting power is provided by the main engine Independent hydraulic station

PLC Control System

Control The Quantity And Cutting Length Automatically.

Input The Production Data(Production Batch,pcs,Length,etc.)On The Touch Screen.

It Can Finish The Production Automatically.

Combined With: PLC, Inverter, Touch Screen, Encoder, etc.