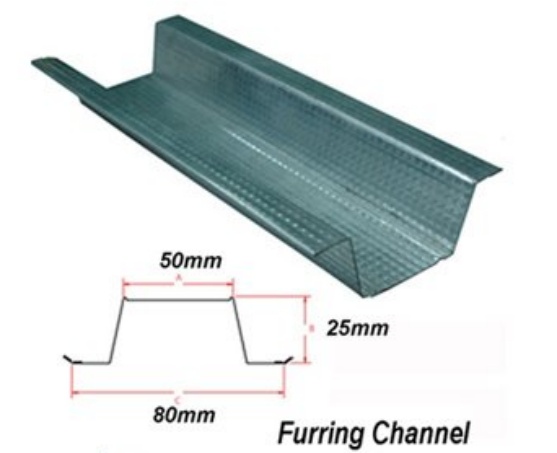

Furr Channel Roll Forming Machine is mainly used for producing cap keels in the field of architectural decoration. Cap keel is a special type of metal keel named after its cross-sectional shape resembling a hat. It is commonly used in ceiling systems to support and fix decorative panels, and is widely used in indoor decoration of commercial buildings, office buildings, hospitals, schools, and other places.

The profile drawing:

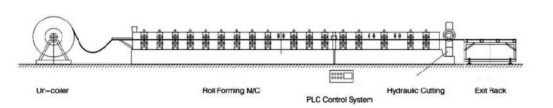

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Furr Channel Roll Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Furr Channel Roll Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.4-0.7mm |

| 3 | Decoiler | 3T |

| 4 | Felt device | Available |

| 5 | Roller station | 11stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 40mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By gear |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | Vertical arch frame structure |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 3kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

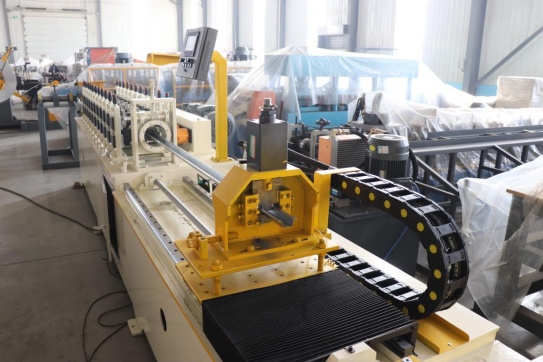

The function of the Furr Channel Roll Forming Machine:

1. High security:

The Furr Channel Roll Forming Machine adopts PLC control and has multiple safety protection measures to ensure safety during the production process. The bed of the equipment is made of welded steel plates and undergoes tempering treatment to eliminate internal stress, avoid deformation of the machine body, and further enhance the safety of the equipment.

2. Easy to operate:

The transmission structure adopts gearbox transmission to ensure that the equipment can operate for a long time and with high intensity. The device is easy to use, easy to learn and use, and can be operated independently after simple training. The mold has high precision, long service life, beautiful appearance, and easy assembly.

3. High production efficiency:

The Furr Channel Roll Forming Machine adopts frequency converter speed regulation and servo cutting technology, with high and stable working speed. The equipment can accurately control the size of the board, the accuracy of the pressure plate, and the rolling speed, ensuring production efficiency and product quality.

4. High degree of automation:

By installing a fully automatic packaging and palletizing line, we can achieve a one-stop automated production process of reverse fastening, bundling, and palletizing, saving time, effort, and labor, greatly improving production efficiency and reducing labor costs.