The forming machine of door shutter is designed to produce shutter door slats batchfully in an automatic way. Our machine can make products thickness from 0.7 to 1.4mm, the shape will be designed by your demand. Click here to watch a video of Australian type shutter door roll forming machine. If you want to make customized machines, such as Zhongtuo rolling shutter door track door rail roll forming machine, continuous PU garage door panel production line, and so on. Please do not hesitate to contact us. If you want to learn more about our company, click here you will acquire the latest news and the most advanced machines.

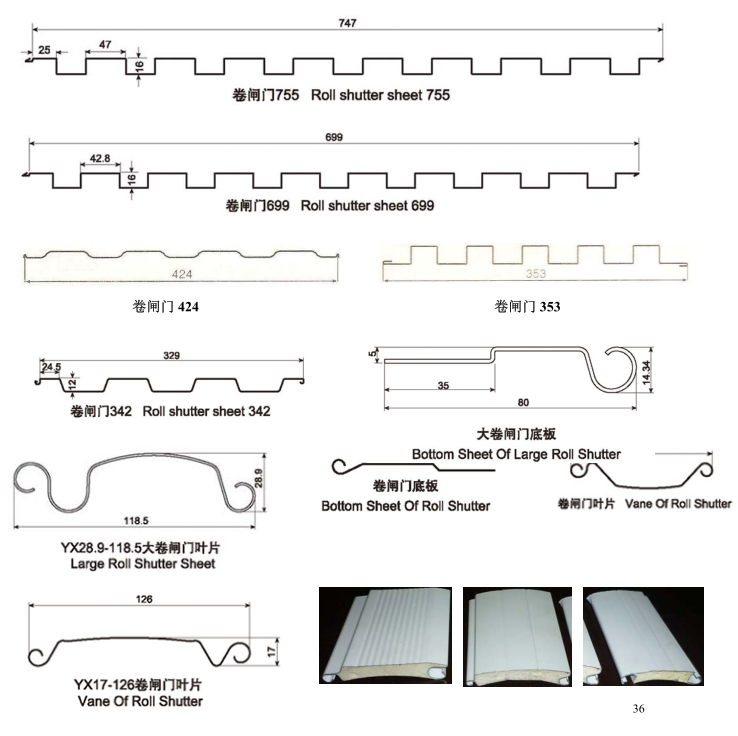

There are drawing profiles of the shutter door slats and applications in our daily life.

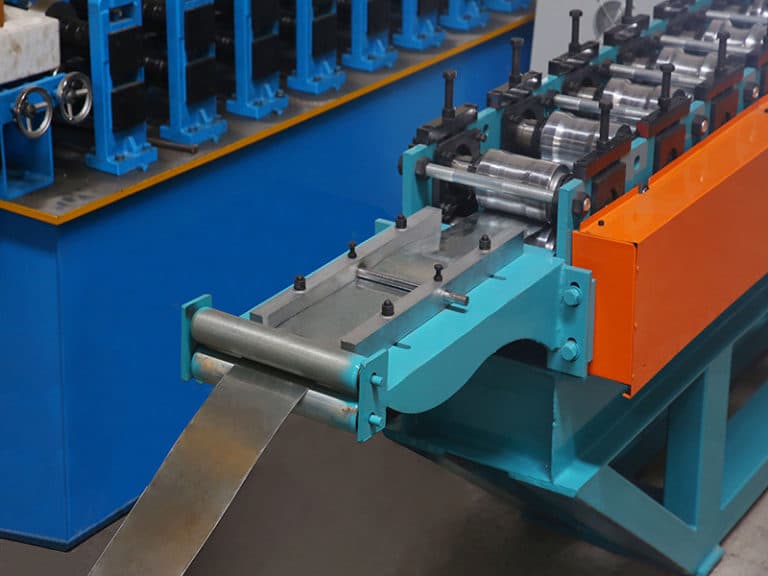

Working profile of the machine:

The shutter door is separated from the wall by the action of the wall, which consists of the curtain plate, the seat plate, the guide rail, the bearing, the reel, the box, the control box, the rollier shutter door machine, the stopper, the lintel, the manual quick release switch, And insurance devices and other parts of the composition, generally installed in the inconvenience to use the wall separated parts. Rolling doors for commercial facade, garage, shopping malls, hospitals, factories and mines and other public places or residential. Especially the larger openings, inconvenience to install the ground door of the place to play a convenient, fast opening effect.

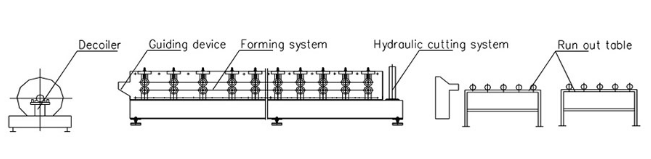

For the forming machine of door shutter, it has many parts:

1. Decoiler the coil.

2.Feeder to the punching holes machine(it can make the shutter door slide cover with holes).

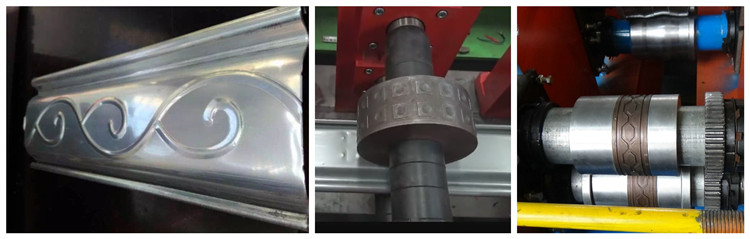

3.Roll forming part, for our mahcine, the forming speed will be 0-30m/min, it is asjustable. Generally we will make the Shutter door roll forming machine with gear drive, it will give machie a strong power to move.

4.Punching the lock holes. This part will together with cutting blade. When it cutting, the machine will punching the holes together.

5.Cutting part. We have two types of cutter for you choose,one is fly saw,another is hydraulic cutter.

The technical details of roller shutter door making machine:

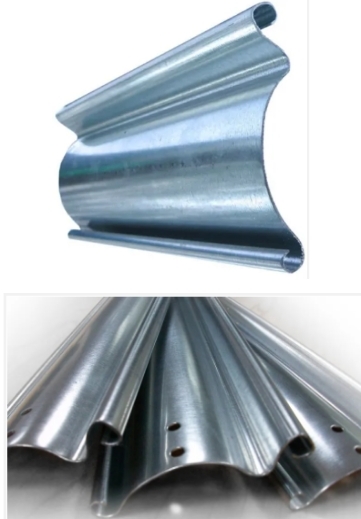

Raw material: galvanized steel

Material thickness: 0.7-1.2mm (depends on customer’s request)

Machine work sped: 20m/min(8pcs/min,2.5m/pcs)

Rolling station: 12 stations

Roller material: GB-Cr12

Transmission: by gear

Drive motor: 4kw

Bearing brand: Harbin