The floor deck roll forming machine-50mm is made to produce 50mm-type floor decks in batch and in an automatic way. ZhongTuo Machinery is specialized in designing and manufacturing customized machines as your requirement. Our machines are equipped with after-sales services and installation guidance from experienced technicians.

Here is a video of floor deck roll forming machine working process for your reference:

Here is a photo of the machine for your reference.

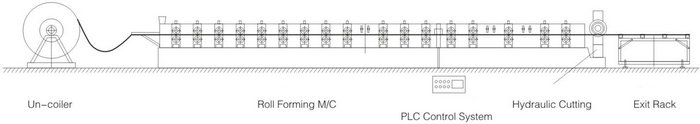

Here is the work flow of floor deck roll forming machine:

Here is some data of floor deck roll forming machine-50mm, including the parameters of materials and details of major components.

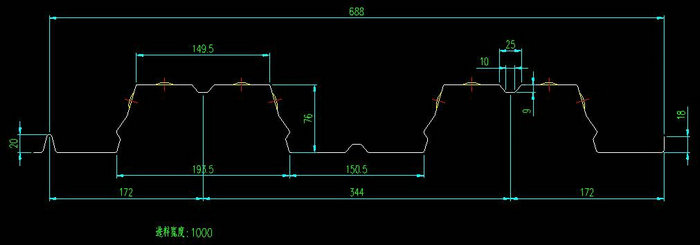

Technical parameters of materials are as follows for your reference:

| Details | Parameter |

| Raw material | Galvanized steel |

| Material thickness | 0.5 – 1.2 mm |

| Material feeding width | 1000 mm |

| Product cutting length | Adjustable |

Packing list of major parts are as follows for your reference:

| No. | Name | Unit | Quantity | Remark |

| Part 1 | 5T decoiler | set | 1 | Manual |

| Part 2 | Main roll former | set | 1 | Chains drive |

| Part 3 | PLC control station | set | 1 | Delta brand |

| Part 4 | Cutting system | set | 1 | Hydraulic |

| Part 5 | Product table | set | 2 | Regular |

Detailed introduction of major component of the machine for your reference:

| Part 1: Decoiler | ||

| Decoiler | Supporting coils and doing uncoiling, passive type, the core moving forward or reverse is pulled by roll forming machine. Shrink and expand core manually |

|

| Carrying capacity: 5 tons | Core inner diameter: 450-550mm | |

| Max coil width: 1250 mm | ||

| Structure: Steel channel welded for the basic frame, profiled bar. | ||

| Advantage: by a big wheel. with manual brake, so operate more easily. | ||

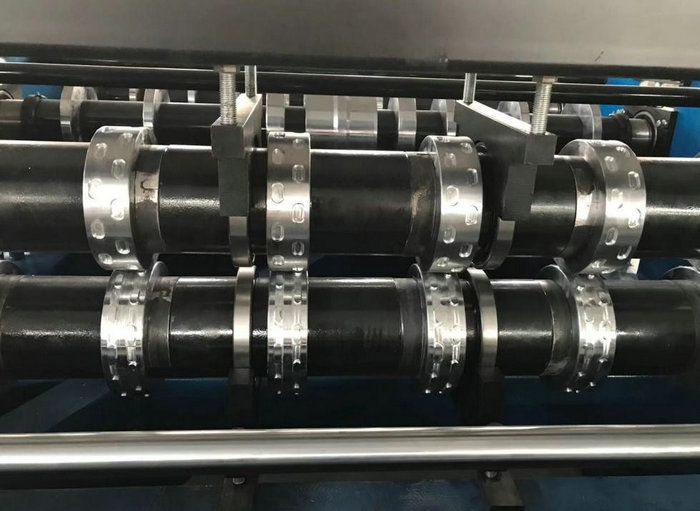

| Part 2: Main roll forming machine | ||

| Roll forming machine | Feeding device | The platform width is adjustable by hand wheel, have the bearing inside to protect the adge of steel sheet. |

| Rolling shaft | Shaft material: 45# steel, surface hard chromium plating | |

| Shaft diameter: 90mm | ||

| Tampering treatment, prevent deformed and improve the hardness. | ||

| Roller | Roller material: Cr15 | |

| Chromed treatment (Cr thickness: 0.05mm), anti-corrosion, increase hardness, ensure the precision and good abrasion performance | ||

| Rolling station | 28 stations, including one set of embossing rolling station | |

| Work speed | 0-15m/min | |

| Machine structure | Middle plate welded structure | |

| Steel plate thickness: 20mm | ||

| Machine basic frame | 350#H steel welded woth diagonal bracing inside | |

| The diagonal bracing can ensure the full set basic frame in the same horizontal level to prevent the sheet shift left or right. Meanwhile it can make sure the machine is in a high stability when working. | ||

| Bearing | Chinese famous brand in Harbin | |

| Work power | 15kw*2 | |

| Brand: China famous brand | ||

|

We adopt two motors driving on the transmission system because of the long rolling stations, it can balance the driving power and ensure all the rolling stations are in the same linear speed, to give the power more evenly to the machine. |

||

| Roller spacer treatment | Anti rusty treatment | |

| Pull rod | Anti rusty treatmen | |

| Transmission | Chain size: 1.5 inches; Double chains driving | |

| Part 3: PLC control system | ||

| Control system | Frequency brand | Delta |

| PLC brand | Delta | |

| Screen type | Touch screen & buttons | |

| Screen language | English/Chinese/Spanish | |

| Lower pressure electrical part | Schneider | |

| Counter brand | Omron | |

| Function | Cutting length control, cutting quantity control, and speed control | |

| Part 4: Cutting system | ||

| Cutting system | Work type | Hydraulic cutting |

| Hydraulic motor power | 5.5kw | |

| Cutter length tolerance | ±10m/2mm | |

| Oil pump | Solenoid valves: 1 set | |

| Frame | Pillar pole type to make sure working steady | |

| Cutting feature | Steady and safe working condition and low sounds | |

| Oil tube and wires connection | All the tubes and wires will be marked by the numbers or letters, so that it will be very easy to connect for the new one. | |