EPS Sandwich panel up layer and down layer panel rolling machine is designed for making the EPS sandwich panel by separately half automatic type. For making the EPS sandwich panel there are two types in the market, fully automatic type and half automatic type. In this part, I will show you the half automatic type, that means by the rolling forming machine, you can make the upper layer and down layer by the rolling forming machine and then do the pasting separately.

EPS Sandwich Roof Panel are applied as external walls and internal division walls, installed vertically or horizontally on single- or multi-span structure buildings.

Features & Advantages

Effective Width: 950mm, 970mm, 980mm, 1000mm, 1150mm

Thickness: 30mm- -250mm

Length :As per requirement considering the transportation constraints.

Light weight 8-14kg/m3

Easy to install, short work cycle

Wide range of designs & Insulation materials.

High load bearing strength

High-resistance to impacts

Sound proof, Moisture Proof

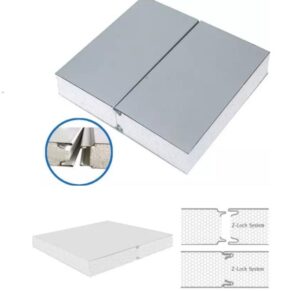

Z-Lock EPS Sandwich Wall Panel

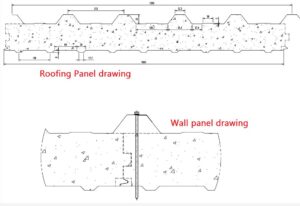

EPS Sandwich Panel drawing profile:

Z-Lock EPS Sandwich Wall Panel rolling machine:\

EPS sandwich panel roofing sheet machine:

No matter the EPS fully automatic production line or the half automatic production line, we also can make for you. If you have any need, please contact us at any time.