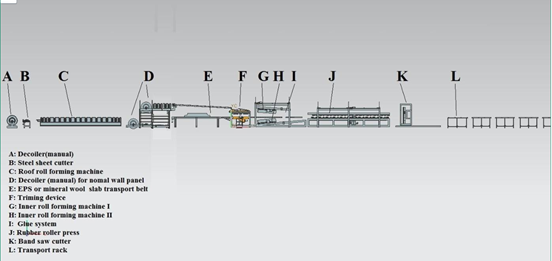

Equipment overview:

The car panel color steel sandwich panel is an ideal material for multi-functional new building decoration. This kind of product has been widely used in various countries all over the world and has become a mature plate. The board can be widely used in large industrial plants, warehouses, paint shops, stadiums, supermarkets, hospitals, cold storage, mobile homes, building plus floors, clean workshops and places that need thermal insulation. It can be widely used in roofing, exterior walls and internal partitions of industrial and civil buildings with fireproof, sound insulation and insulation requirements, especially for projects with high fire protection requirements.Roll forming machine

The double-sided color steel sandwich composite board unit of the compartment board is a thin double-layered high-strength material laminated on the double-sided outer layer of the thicker and lighter inner core material, forming high strength, light weight, good heat insulation effect, strong and durable, A new type of building material with a beautiful appearance. The outer layer is generally made of a 0.3-0.6 mm color steel plate, and the inner layer is a 0.25-0.5 mm color steel plate. The inner core adopts EPS expandable self-extinguishing non-flammable polystyrene, foamed polyurethane and rock wool, and the thickness can be arbitrarily selected between 50-250mm.

The production line adopts advanced production technology with gas, electricity and machinery as one. It is special mechanical equipment for processing color steel sandwich panels. The working speed is variable frequency stepless speed regulation, which can be combined at one time. The complete assembly line is discharged by the feeding mechanism and pressure type. The mechanism and composite mechanism (compression gluten, rubber coating, heating, compounding, and crimping, slotting, trimming, pneumatic, automatic cutting) are indispensable equipment for producing industrial plants, warehouses and other wall panels.

The production line is professional equipment for producing car panel color steel sandwich panels.

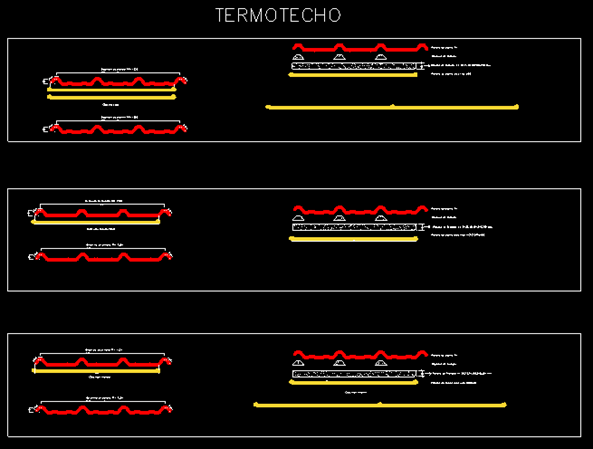

Take the following drawing profiles for your reference:

Machine working flow:

Passive Unwinder 2 sets—Hand-placed EPS sheet equipment—Foam and rock wool milling edge—Flanging wheel flanging—spraying glue-soaking glue—compositing—cutting machine cutting– – discharging (manual lifting)

| Main elements of the Machine | ||||

| Coil feeding device | ||||

| NO | Elements | Function | Requirements | |

| 1-1 | Decoiler with the bridge | With the main machine speed to feed the coil to machine | Loading weight5t,Inner ID 520mm, | |

| 1-2 | Shearing system | If you need to cut any length | Manaul cutter | |

| 1-3 | Spray glue system | According to different profiles and spray the glue. | ||

| 1-4 | Glue pump two sets | Device for proportionally supplying glue

Stepless speed regulation, range 0-0.4kg/m2 |

||

| 1-5 | EPS Rib making | The excess material of the core material of the core material is milled, and the size of the milling cotton can be finely adjusted. | ||

| 1-6 | Double bag vacuum cleaner | Absorbing core material that has been milled | ||

| 1-7 | Press and push devide for EPS | The core material can be adjusted between 40-250mm and automatically conveyed at the same speed. | ||

| 1-8 | Main body and coil feeder | Main machine | ||

| Sandwich panel elements | ||||

| NO | Elements | Function | Requirements | |

| 2-2 | Sizing devide | Sense the length of the finshed products | ||

| 2-3 | PLC operation | The whole production line is controlled by PLC | ||

| 2-4 | Heating Pipe | Adjust the temperature of the upper and lower plate processing zone | ||

| Shearying system | ||||

Why choose ZT EPS Rockwood Sandwich panel production line?

- Make sure the shape is more beautiful, the panle is flat.

- Make sure the working is safe.

- The machine working is lower noise and more clean when working.

- The rolling shape is more accurate and cutting length is more accurate also.

- The motor and other PLC elements, we use the world famous brand.

Here are some finished product pictures for your reference: