Drywall roll forming machine is used to make steel C profile stud sheets or U profile track sheets according to customers’ different requirements. These finished products are applied for both exterior and partition walls in both individual and industrial buildings. ZhongTuo can manufacture customized drywall roll forming machines if you have your own needs and drawing profiles. Here are some videos of our machine that are popular in different countries and areas.

High speed fully automatic Stud and track rolling machine for Canada

Combied type stud and track rolling machine for Australia

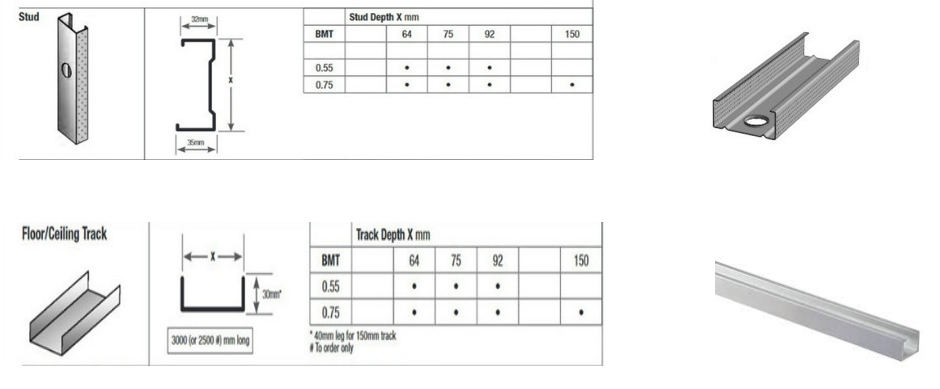

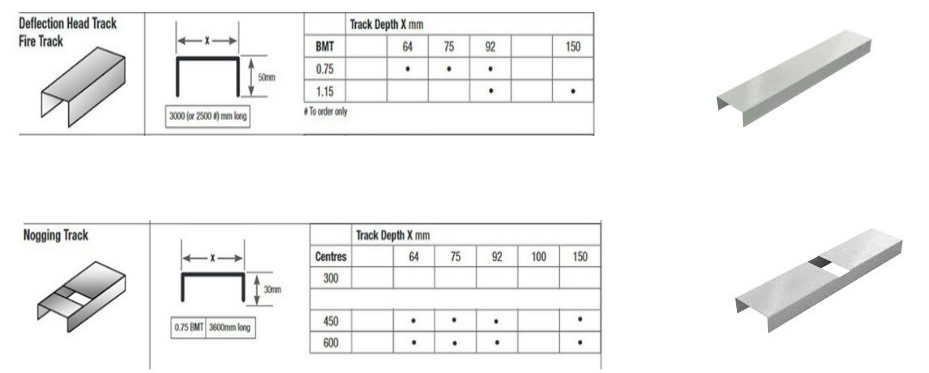

Parameters of finished metal studs and tracks:

As you can see from the pictures above, the drywall roll forming machine produces various profiles and sizes of studs and tracks. The studs and tracks are made from galvanized steel. The machine is fully automatic and can manufacture these products batchfully in a short time, helping you to save time and lower labor costs.

Applications of finished products:

- Hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings.

- Renovation of old buildings

- Interior decorations, ceilings and other places

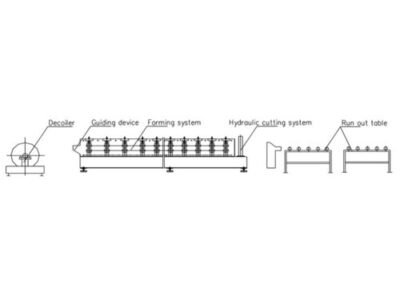

Work flow:

Advantages of drywall roll forming machine:

1. The machine is stableand shakeless withou noise.

2. The machine is controlld by computer, PLC display, which has touchable screen, and the operation is easy, running is steady and reliable, endurable.

3. Cutting machine is characterized by stable driving, easy operation.

4. Hydraulic system use the hydraulic pump, long operating life and noiseless.

Technical specifications of our machine:

| No | Name | Unit | Qty | |

|

1 |

Man-made decoiler |

set |

1 |

*Max width 300mm *Inner diameter -450-550mm *Max loading capacity 1.5T *Manual operating type manual expansion to tighten the coil *Break down drive whole line stop while decoiler idle |

| 2 | Feeding Table | set | 1 | |

|

3 |

Forming Rollers |

set |

1 |

*Forming Station 12 *Forming Rollers material Cr12 *Forming Rollers hard treatment HRC 58-60 *Shaft of roller Diameter 40mm *Shaft material 40Cr,heat treatment, refine grinded *Machine frame: steel welding *Main sidewall thickness 20mm *Machine driven by universal joints via gearbox *Roll forming motor 5.5kw with frequency inverter controller *Gearbox RV worm gearbox |

|

4 |

Hydraulic cutting with hole punching |

set |

1 |

*Hydraulic pump stand 1 set |

|

5 |

Profile Discharger |

set |

1 |

*Driven machinical Auto Head *Operation Full automatic along with forming machine |

|

6 |

Electric Control system |

set |

1 |

Delta control system |