The double-layer roof sheet roll forming machine is mainly used for efficient and mass production of roof tiles, which are widely used in the construction industry for roof and wall covering. This machine can simultaneously produce trapezoidal roof tiles and curved roof tiles.

The roof tiles produced by the double-layer roof sheet roll forming machine are widely used for roof and wall covering in various buildings due to their lightweight, high strength, waterproof, fireproof and other characteristics. Common application scenarios include factories, warehouses, carports, sports halls, etc.

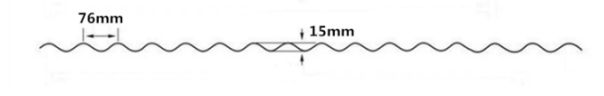

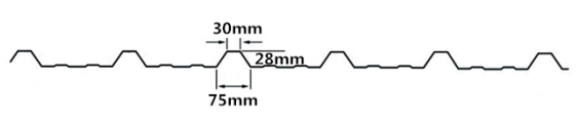

The profile drawing of the first layer machine:

The profile drawing of the second layer machine:

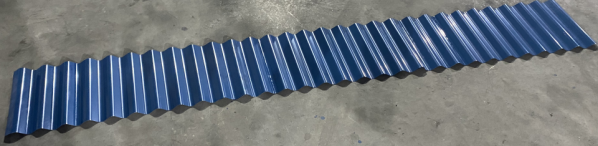

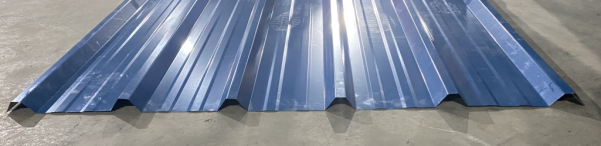

The pictures for the finished product:

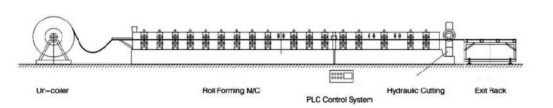

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Double Layer Roof Sheet Roll Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Double Layer Roof Sheet Roll Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 15stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Double Layer Roof Sheet Roll Forming Machine:

1. Improve production efficiency:

The double-layer roof tile machine adopts a double-layer design, which can simultaneously process two layers of panels, greatly improving production efficiency and material utilization. Through continuous production, it is easy to meet the needs of large-scale production.

2. Cost savings:

The design of the double-layer roof tile machine reduces the footprint of equipment and factories, and lowers land and space costs. Meanwhile, the produced tiles can be used for the roofs and walls of buildings, saving on building material costs.

3. Improve product quality:

Through high-precision processing technology, the double-layer roof tile machine can ensure the accurate size and uniform texture of the tiles produced, improving the quality and consistency of the products.

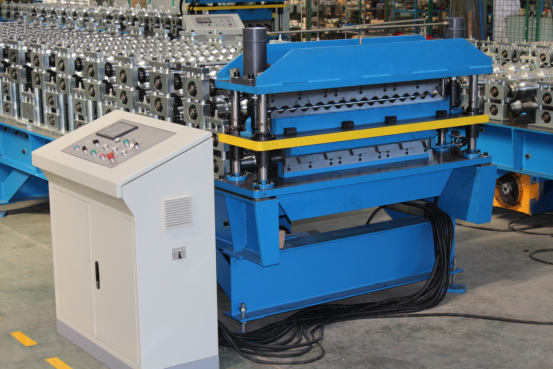

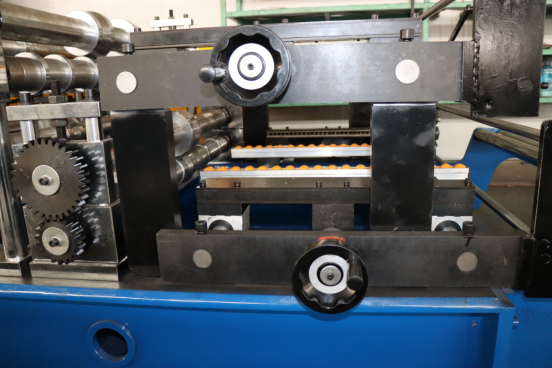

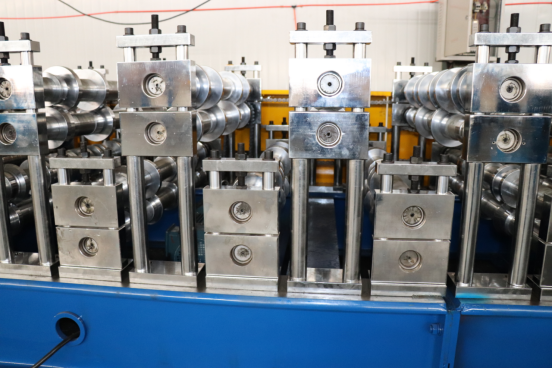

Machine photos: