The Double Layer Roof Sheet Roll Forming Machine used for producing roof sheets, which significantly improves production efficiency and economy through its double-layer design. Compared with traditional machine, the output of double-layer tile pressing machines can be nearly doubled, bringing greater economic benefits to enterprises, shortening production cycles, and accelerating production efficiency.

The profile drawing of the first layer machine:

The profile drawing of the second layer machine:

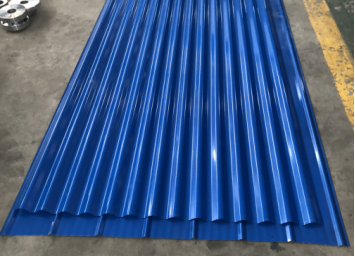

The pictures for the finished product:

Packing list of the Double Layer Roof Sheet Roll Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Double Layer Roof Sheet Roll Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 14+16stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

Main features:

1. Efficient production: The double layer design enables the equipment to produce two different models simultaneously, improving production efficiency and flexibility.

2. Small footprint: The double layer roof sheet roll forming machine can be used for both purposes, saving space, facilitating transportation, and saving costs.

Now I will introduce the double layer roof sheet roll forming machine,this type is very popular.

Part 1:Decoiler

Part 2:The feeders

Part 3:Cutting device

Part 4:Control system

Part 5: Hydraulic system: