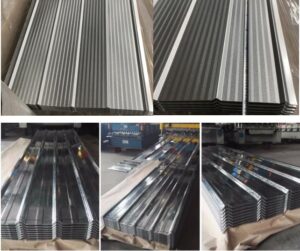

Double layer 5V roof sheet and corrugated sheets rolling forming machine for Chile market is quite popular in the Chile. Based on the market requirements, we design this double layer roofing sheet machine for Chile market. Here are two popular drawing profile for your reference:

| Raw material | PPGI,PPGL,GI,GL,Aluminum |

| Raw material width | According to the profile of the machine, we can free to design the profile for the customer |

| Frame | 350H steel/400H steel/ Or customized |

| Side panel | 16mm/18mm/20mm according to the machine quality |

| Roller | 11-24 rows according to specification of the product |

| Roller material | #45 steel, forged and chrom-plated |

| Motor | Delta/Siemens/ Or customized |

| Motor power | 5.5Kw/7.5Kw/ Or customized |

| Drive way | By chain |

| Chain size | 1 inch/ 2inch / customized |

| Cutting way | Hydraulic cutting |

| Cutting blade material | Cr12 mov |

| Hydraulic power | 5.5Kw/7.5Kw/ Or customized |

| Control system | PLC control system,(the operate table can rotate 360°) |

| PLC brand | Delta/Siemens/ Or customized |

| PLC language | Chinese/English/Spanish/Russian |

| Cutting tolerance | ±2mm |

| Speed | 8-12m/min (if customer need the more speed, we will design by using the servo motor) |

Double layer 5V roof sheet and corrugated sheets rolling forming machine:

| Double layer metal roof profile machine | ||||||

| No. | Name | Unit | Qty | Remark | ||

| Part 1 | 5T manual decoiler | set | 1 | You can choose hydraulic one instead | ||

| Part 2 | Guide feeding device | set | 1 | With hand cutter | ||

| Part 3 | Main roll former | set | 1 | Chains drive | ||

| Part 4 | PLC control station | set | 1 | Delta brand | ||

| Part 5 | Cutting system | set | 1 | Hydraulic | ||

| Part 6 | Hydraulic oil pump station | set | 1 | With cooling fan | ||

| Part 7 | Simple collect table | set | 1 | You can choose automatic stacker instead | ||

| Part 8 | Spare parts | set | 1 | |||

Advantages of Double layer 5V roof sheet and corrugated sheets rolling forming machine for Chile market:

- For the leveling rollers and handrail for easy to feed coil and protect the surface of the coil.

- Strong base frame for long time to use and double chain to make sure the machine transmission powerful.

- For the shearing part, we use the strong and high quality hydraulic jacks for you to use. We use the strong holding board to protect the cutter holder.

Here is the machine working video for your reference: