Door Frame Roll Forming Machine

This door frame roll forming machine is designed for making the door frame production in batch fully automatically.

And this metal profile is popular in India, and other counties.

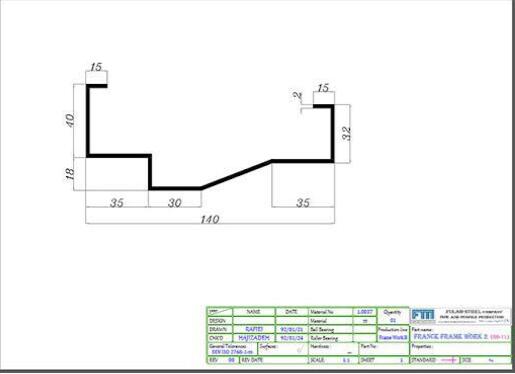

Door frame drawing profile for your reference:

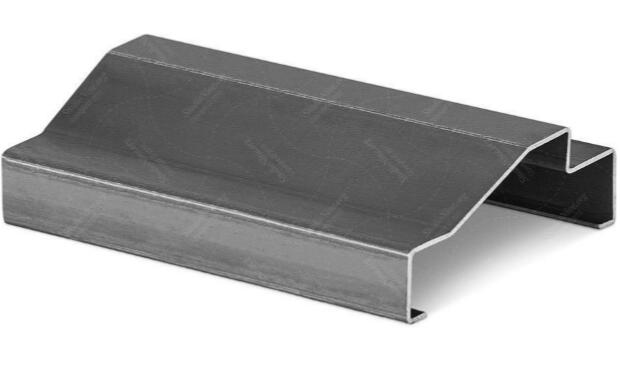

Finished product profile:

Based on the customer requirements and our experience, we design the door frame Roll Forming Machine like following picture:

The door frame Roll Forming Machine is composed by the following elements:

- 3T Manual/hydraulic decoiler

It is used to support the steel coil and uncoil it in a turntable way.Passive uncoil pulled by roll forming system.

2.Main Roll Forming Machine

a.Feeding and leveling part Putting the raw material through the platform for manufacturing and processing, can ensure the products are clean, parallel and everything is uniform. Consult the equipment regulation for the function of locating their on panel.

b.Roll forming

After leveling,the steel plate will enter this part for forming.

Voltage: 380V/50HZ3Phase(ascustomer’srequest)

Roller fixer:Guide column

Frame:pillar frame Memorial arch frame type

Frame thickness: 25mm

3.Hydraulic Shearing

Shearing part

After roll forming,the product will be cut at this part. Material ofblades:Gcr12 quenched

Power supply:hydraulicpower Stroke switch:non-contact photo electric switch .

Hydraulicstation 46#

hydraulicoil 5.5kw

Hydraulic power Components: The system includes one set of hydraulic tank, one set of hydraulic oil pump, two hydraulic pipes,and sets of electromagnetismvalves.