The CZ steel integrated machine is mainly used for producing CZ steel, which has a wide range of applications in the construction and industrial fields. A machine can produce steel of various shapes and sizes, such as C and Z sections, to meet different needs.

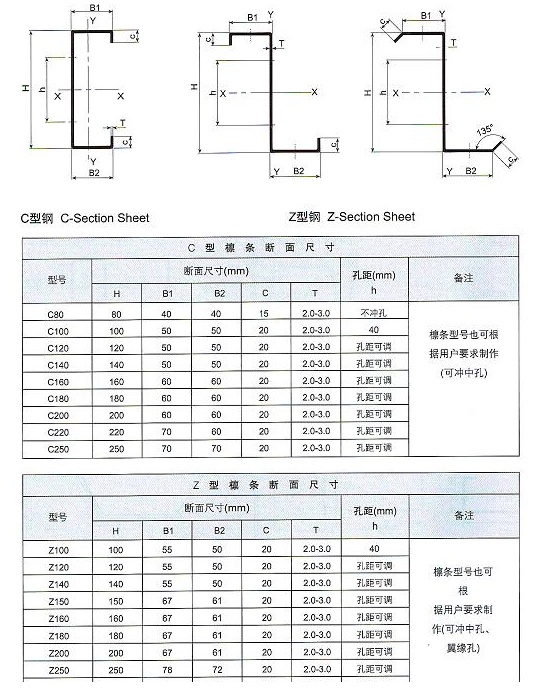

The profile drawing:

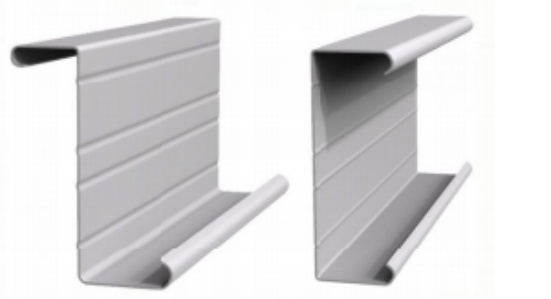

The pictures for the finished product:

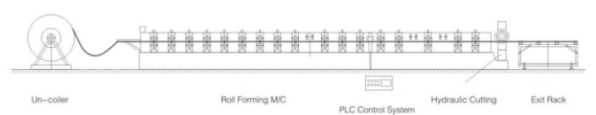

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the CZ steel integrated machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the CZ steel integrated machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 1.5-4.0mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 14stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 70mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 18.5kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 11kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the CZ steel integrated machine:

1. High degree of automation:

The equipment has fully automatic functions, which can automatically complete the conversion from C-type to Z-type, adjust the thickness gap of raw materials, and adjust the roll gap, reducing manual intervention and improving production efficiency.

2. Quick changeover:

The CZ steel integrated machine supports quick changeover, and some equipment can complete any changeover within three minutes.

3. Production of multiple specifications:

This equipment can produce various specifications of C-shaped steel and Z-shaped steel to meet the needs of different building structures.

Some details of the CZ steel integrated machine: