C&Z galvanized section roof purlin making machine is a kind of cold roll forming machine that is used to produce C-shaped and Z-shaped steels. The finished pruducts, C&Z purlin, are widely applied in supporting residential and commercial buildings as well as solar panel mounting structure and cable tray. Our C&Z galvanized section roof purlin making machine is easy to operate with the touch screen controller PLC. This kind of machine can change the profile and specifications automatically without replacing rollers if different sizes of products are needed.

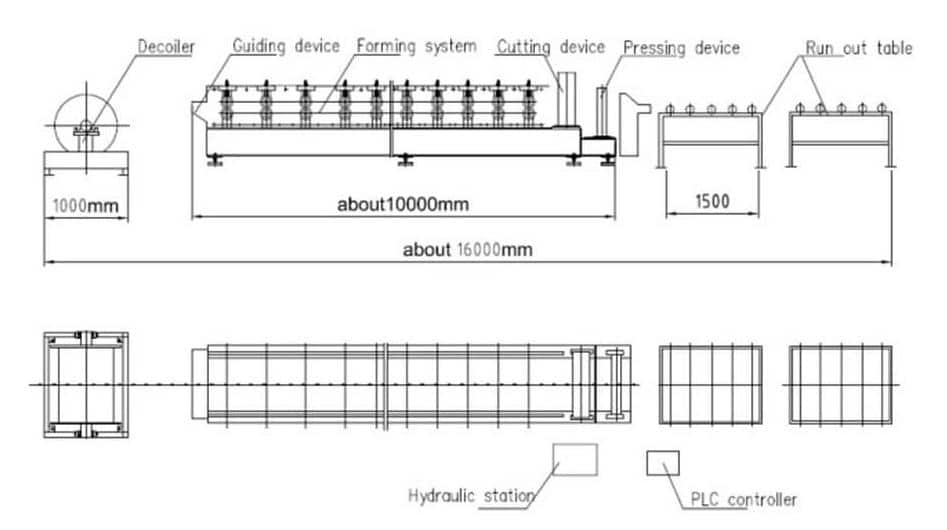

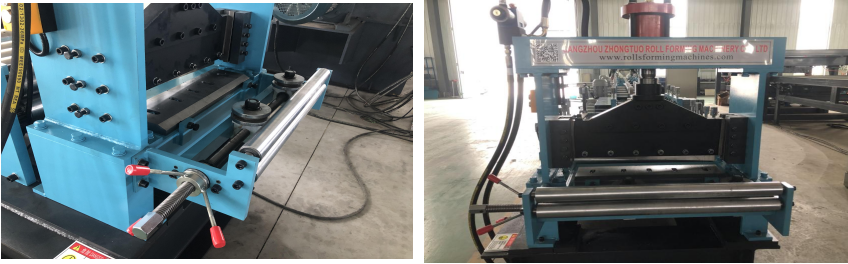

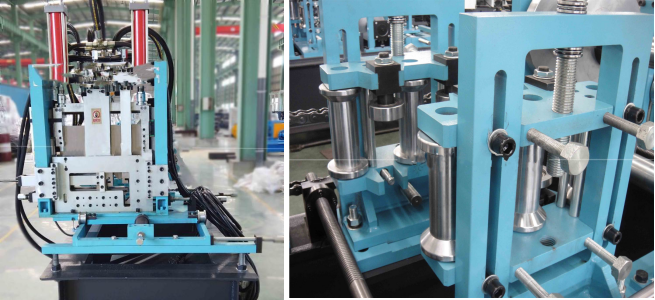

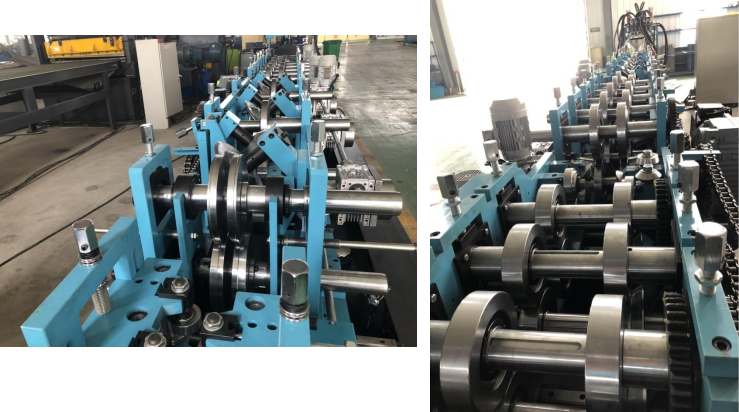

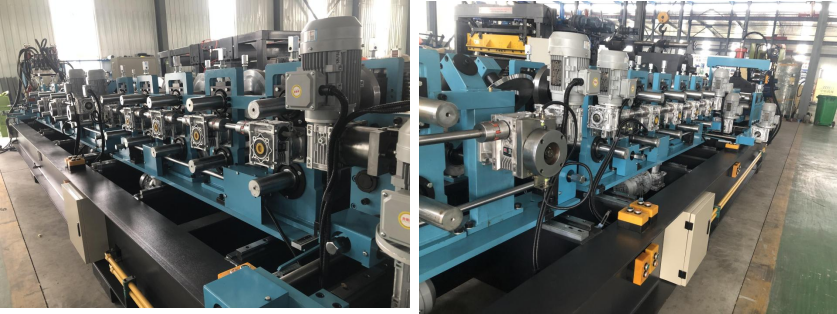

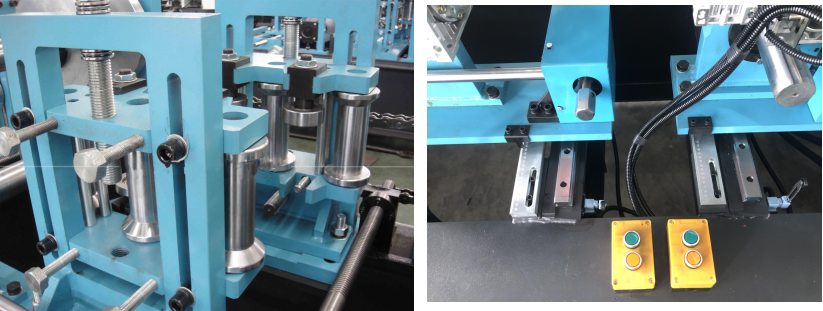

Here is the pictures of C&Z galvanized section roof purlin making machine:

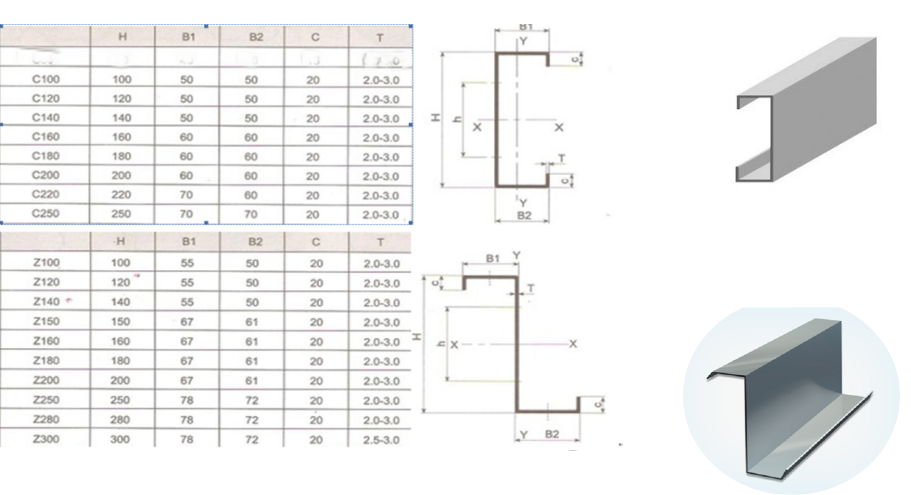

Here is the picture showing the size range and thickness range of standard C&Z purlins:

With the rapid development of roll forming technology, our company can offer you not only the size of products displayed above, but also different sizes of C purlins and Z pirlins as your different requirements. These finished products are made from galvanized steel or carbon steel. The material thickness is from 1.5mm to 3.0mm, width from 200mm to 600mm, and the effective width is from 80mm to 300mm. If you are interested in our machines and have your own profile drawings, please contact us and we will provide you with customized specifications of products.

Applications of finished products:

- Industrial buildings

- Hall and warehouse construction

- Extended construction and renovation

- Agricultural activities

Brief introduction of our machine:

- Speed: Max. 25m/min (except of cutting and punching)

- Dimension: 9500*1500*1400

- Voltage: 380V, 3P, 50HZ (Customized)

- Material: Galvanized steel

- Yield strength: 235Mpa, 345 Mpa, 350Mpa

- Control system: PLC

- Cutting system: Hydraulic

Features of our machine:

- It offers a rapid change rollformer for allowing the operator to select a flange height change in minutes and not hours.

- The web width change in an infinite range from 100mm up to 300mm fully automatic.

- It supports produce purlin in pre-painted, in galvanized and also the use of Hot Rolled steel.

- High accuracy with punching and high speed from uncoilers, as well as a wide range of hole punching systems for inline web and flange hole placement with high accuracy.

- Automation of gapping the roll tooling for different thicknesses can be added so that your operator does not have to adjust the top shaft for material thickness changes.

Working Flow:

Hydraulic Decoiler — Guiding device — Hydraulic Punching — Roll-forming — Cutting device — Run out table

More detailed options of our machine for your customized specifications:

1. Stacker (Optional): One is 3 or 6-meters manual, and the other is fully automatic stacker with package.

2. Decoiler (Optional): As for decoiler, you can choose the manual one or the automatic one. Here are some pictures for your reference:

3. Shearing (Optional):Pre-shearng, this is optional, you can choose you need or not. It can help you remove the untidy part at the very beginning.

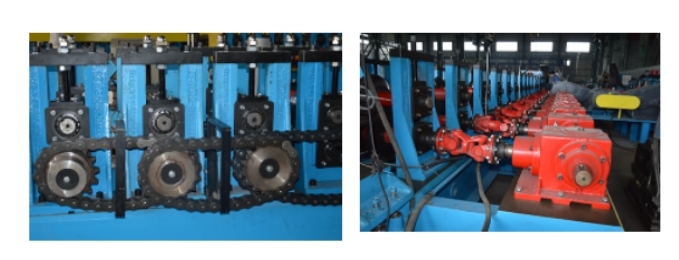

4. Drive: There two types of drive, chain type and gearbox type.

5. No-limited shearing: For this part, we have options stop shearing and high speed non-stop shearing.

6. Leveling system: We have equipped this part with top 3 and bottom 4 rollers, and extra 2 couples of pinch rollers. The leveling roller diameter is ø80/100mm.

7. C&Z Change: turn over the roller box to 180 degree.

8. Size change: Size can be changed by pressing buttons. Motor drive, electrical control, continuously adjustable.

9. The machine includes 10 sets of special roller straightening unit and another 4 sets of roller straightening unit to ensure purlin will not cause curve, bow, sweep or twist.

10. Add the metal embossing roller. Those days for making the anti-slip profile, we also add the metal embossing rollers. If you need, we can also add for you.

For this machine, now let us check and machine working video.