The Corrugated Roofing Sheet Roll Forming Machine adopts advanced forming technology and materials, and through precise mechanical transmission and control system, presses raw materials into tiles with arc shape. With efficient production capacity, it can quickly complete the pressing work of a large number of tiles, meet the needs of large-scale production, and is widely used in fields such as construction, decoration, and landscaping.

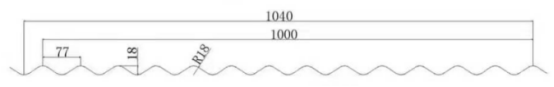

The profile drawing:

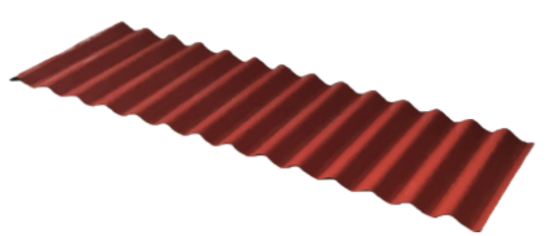

The pictures for the finished product:

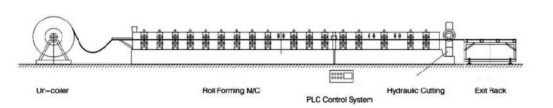

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Corrugated Roofing Sheet Roll Forming Machine :

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Corrugated Roofing Sheet Roll Forming Machine :

| Item | Name | Specifications |

| 1 | Raw material | PPGI |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 16stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350mm H steel welded |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Gcr12 quenched treatment |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Corrugated Roofing Sheet Roll Forming Machine :

1. Provide production of building materials:

The Corrugated Roofing Sheet Roll Forming Machine can produce building materials such as arc wave glazed tiles or color steel tiles suitable for roofs.

These materials have the characteristics of light weight, high strength, large load-bearing capacity, and good seismic resistance, which can meet the demand for high-quality roofing materials in the local construction market in Peru.

2. Adapt to architectural style requirements:

The tiles produced by the Corrugated Roofing Sheet Roll Forming Machine have beautiful arc waveforms and are suitable for use as roof covers in personal residences, private villas, park and square buildings, etc.

The shape and style of these tiles can be combined with the local architectural style of Peru to enhance the appearance and overall beauty of the building.

3. Responding to natural environmental challenges:

Earthquake activity is frequent in some areas of Peru, and the building materials produced by the Corrugated Roofing Sheet Roll Forming Machine have good seismic performance, which can improve the safety of buildings in natural disasters such as earthquakes.

In addition, its products also have wind and fire resistance properties, which can effectively resist disasters such as strong winds and fires, ensuring the safety and durability of buildings.

Machine photos:

Some details of the Corrugated Roofing Sheet Roll Forming Machine :