The corrugated roofing sheet roll forming machine is mainly used to produce corrugated roof tiles, which are widely used for roof covering of various buildings. This machine not only guarantees production efficiency, but also supports customized services to meet different needs. They are widely used in various buildings, such as antique factories, tourist attractions, hotels, etc., providing beautiful and durable roof tiles.

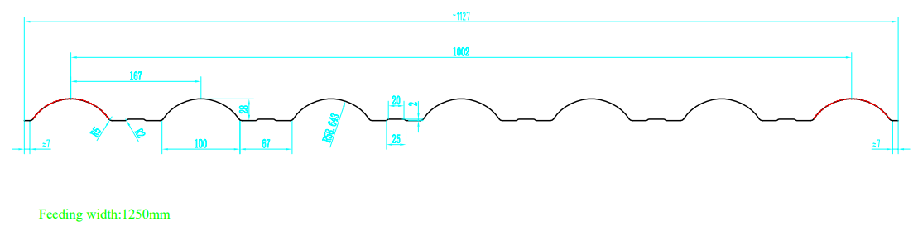

The profile drawing:

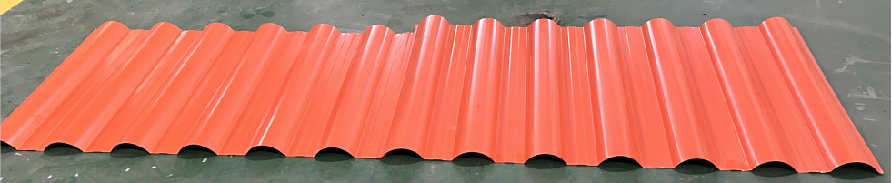

The pictures for the product:

The technical specifications of the corrugated roofing sheet roll forming machine:

| Item | Name | Specifications |

| 1 | Raw material | Galvanized steel and Pre-painted steel |

| 2 | Raw material thickness | 0.3-0.5mm with press0.45-0.6mm without press |

| 3 | Decoiler | 5T Manual decoiler(Different capacity for option,hydraulic one for option) |

| 4 | Roller station | 20 stations |

| 5 | Roller material | 45# steel with quenched treatment |

| 6 | Shaft diameter | 80mm |

| 7 | Shaft material | 45# steel with tempered |

| 8 | Transmission | by chain |

| 9 | Motor power | 7.5kw Servo motor |

| 10 | Machine frame | 350H steel welded |

| 11 | Cutting type | Hydraulic cutting |

| 12 | Hydraulic power | 5.5kw |

| 13 | Cutting blade material | Cr12 with quenched treatment |

| 14 | Cutting tolerance | +/-1mm |

| 15 | Control system | PLC |

| 16 | Brand | PLC:Delta/Siemens/MitsubishiTouch screen:Delta/Siemens/MitsubishiEncoder:Omron |

The Components of each part and Introduction:

Part 1:Decoiler

The capacity of decoiler:For normal coils which is used in roofing sheet,the 5 tons capacity is enough.If customers have special request about the capacity,we also support customization as customer’s request.

Part 2: The roll forming machine

(1) For the feeding part, we use the roller design to protect the surface of the coil.

(2) For the transmission, we use the double chain.

(3) For the base frame, we use the strong with more supporting to make sure the machine working more steady.

(4) For the main motor we use Siemens, if you need we can customize according to your needs.

(5) For the shearing part, we use two pillar supporting shearing to make sure the shearing more accuracy and long time to use.

(6) For the rollers are with the key note and good chroming to make sure long time to use.

(7) We add the clutch in the double layer machine,which can reduce the abrason of the rollers.

Part 3: Control system

Touch screen:Delta,Siemens,Mitsubishi

PLC:Delta,Siemens,Mitsubishi

Low voltage apparatus:Schneider

Encoder:Omron

Part 4: Hydraulic system

1.Work type:Hydraulic

2.Motor power:5.5 kw

3.Cutting blade material :GB-Cr12 mould steel with quenched treatment

4.Cooling system:By fan