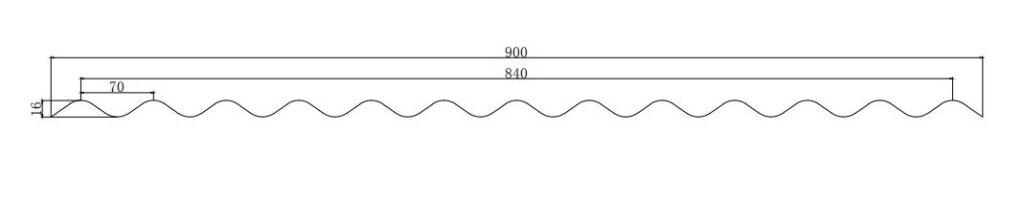

As the name suggests, corrugated roofing sheet machine is designed to produce a batch of corrugated sheets automatically. Being a mature manufactuerer of different types of machines, we are able to offer high-quality corrugated roll forming machines for you. Customized specifications are all available. Here is a drawing profile for your reference:

Finished corrugated sheets produced by our high-end machine:

Picture of corrugated roofing sheet machine:

A corrugated sheet roll forming machine typically includes the following components:

- Manual decoiler

- Feeding guide

- Roll forming system

- Transmission system

- Hydraulic system

- Control system

- Hydraulic cutter

- Oil pump

- Runout tables

Technical Parameters of the Corrugated Sheet Roll Forming Machine:

- Raw Material: Prepainted color steel coils; Galvanized steel coils; Galvalume steel coils;

- Yield strength: 235MPA-550MPA;

- Raw Material Thickness: 0.3-0.8mm;

- Raw Material Width:914-1250mm;

- Main Power: 5.5 KW;

- Forming stations: 16-22 stations;

- Stands structure: Conjoint type OR Individual Type

- Machine Frame stand: 36# H Beam steel welded

- Thickness of Steel Frame: 18mm

- Material of Roller: High grade 45# steel, Polished and coated with 0.05mm hard chrome

- Shaft Material: High grade 45# steel

- Diameter of shafts: 70mm

- Hydraulic Cutter: Stop to cut

- Material of cutting dies: Cr12 steel

- Hydraulic power for cutting: 4KW

- Cutting lengths and quantities: Clients can set required lengths and quantities through the touch screen on PLC control box.

- Control system: Panasonic PLC, Inverter, CHNT transformer and Omron encoder

Working flow:

Manual decoiler——Feeding——Roll forming——Hydraulic stamp and cutting——Output table