Corrugated roof tile machine is a specialized equipment for producing circular roof tiles, widely used in the construction industry, especially for buildings that require special shaped roofs, such as personal residences, private villas, park and square buildings, etc.

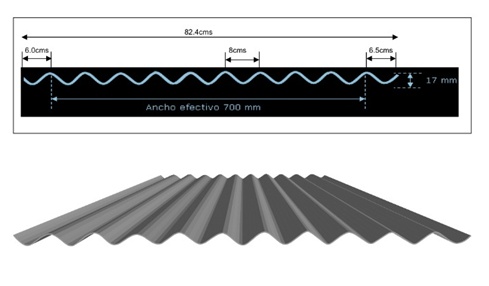

The profile drawing:

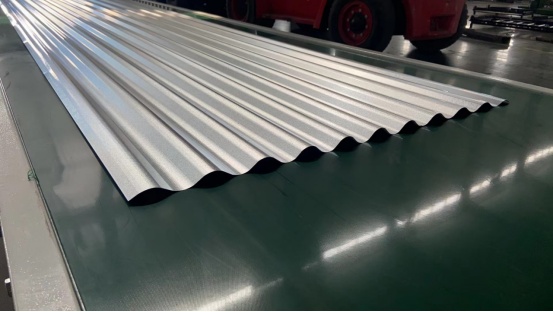

The pictures for the finished product:

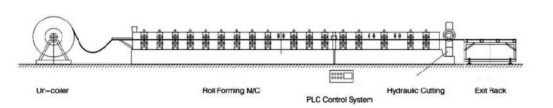

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Corrugated roof tile machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Corrugated roof tile machine:

| Item | Name | Specifications |

| 1 | Raw material | Galvanized steel,Q235 |

| 2 | Raw material thickness | 0.18-0.28mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 20stations |

| 6 | Roller material | High grade 45# steel,chromed treatment |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | High grade 45#,Tempering treatment |

| 9 | Transmission | By double chains |

| 10 | Motor power | 7.5kw |

| 11 | Machine frame | 400mm H beam structure |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Gcr12 quenched treatment |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Corrugated roof tile machine:

1. Improve the waterproof performance of the roof

The design of the Corrugated roof tile gives it good waterproof performance. Its curved structure can effectively guide rainwater to be quickly discharged, reduce the amount of water in the roof area.

2. Enhance the stability of roof structure

Corrugated roof tiles are usually made of high-strength metal materials or composite materials, which have high wind and earthquake resistance performance.

Its curved structure can disperse wind and pressure, enhance the overall stability of the roof, and is particularly suitable for coastal areas or construction projects with strong wind.

3. Improve production efficiency

The Corrugated roof tile machine can achieve efficient and stable tile production through automated production processes. Its main advantages include:

Automated operation: The equipment is equipped with an advanced PLC control system, which can achieve automatic feeding, forming, cutting, and stacking, reducing manual intervention and improving production efficiency.

High precision forming: using high-precision roll forming technology to ensure the consistency of tile size and shape, reducing waste rate.

Diversified production: The equipment can adjust the molds and process parameters according to customer needs to produce arc-shaped tiles of different specifications and shapes, meeting diverse market demands.

Machine photos: