Ceiling system T grid machine consists of three important parts, which are main T machine, cross T machine and wall angel machine. Our company have three production lines of T bar making machines. There is narmally a stab connection on the cross Tees, therefore, these fnished products are very secure. These finished products are widely used in residential and commercial buildings. The ceiling T Grid Rolling Forming Machine now is quite popular. Here we will introduce you main T machine, cross T machine and wall angel machine.

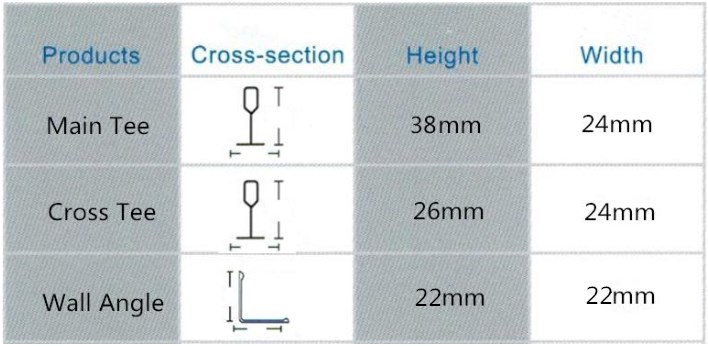

Here let me show you the machine products: main T, cross T and wall angle. The three products work together. Wall angle is installed on the wall and main T grid and cross T grid cross each other. The function of wall angle is to support the structure and at the same time it looks beautiful. After that we can put the ceiling panel on the structure, then the ceiling system is ready. This kind of ceiling system can improve the working efficiency and at the same time and is easy to repair if there is some damage.

Examples of applications of T Grid:

- Engineering reinforcement

- Agricultural and hardware machinery accessories

- Embeded parts used in railway and house foundation

Intriductions of our ceiling system T grid machine:

We have rich experience in designing and making the T grid forming machine. And we are able to manufacture customized T grid forming machine as your different profile drawings.

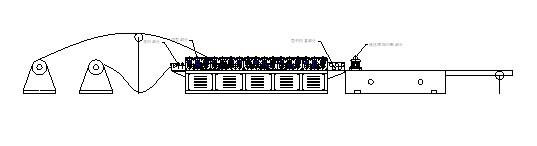

1. Main T grid forming machine:

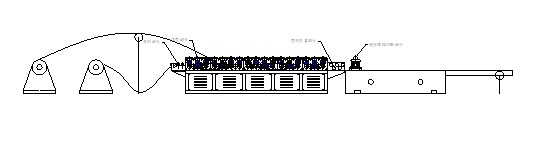

Main T grid forming machine consists of Single or Dual Head Type decoiler, Roll forming main machine, Hydraulic, Automatic Punching and cut-off Device, run-out table, PLC Automatic Control Cabinet.

Parameters of main T grid forming machine:

| Forming Roller Stations: | 15—-18 Stations |

| Forming Roller shaft: | φ36mm |

| Forming rollers | GCr15, Quenching, hardness HRC56-62º |

| Forming Speed: | 12 meters / min |

| Main motor: | 5.5kw |

| Sheet Thickness: | 0.3 to 0.35 mm |

| Cutting mode: | Hydraulic automatic punching and cutting machine |

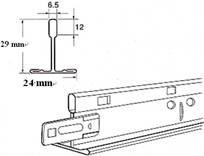

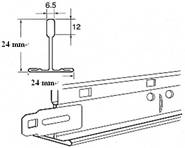

Here is a pocture of Main T grid Profile for your reference:

Metal thickness: 0.28mm

Length: 3,600mm

2. Cross T grid forming machine:

Cross T grid forming machine consists of Single or Dual Head Type de-coiler, Roll forming main machine, Automatic Punching and cut-off Device, run-out table, PLC Automatic Control Cabinet, etc. The profile drawing of main components is showed as follows.

Parameters of cross T grid forming machine:

| Line structure | Portal-type frame style |

| Forming Roller Stations: | 15—-18 Stations |

| Forming Roller shaft: | φ36mm |

| Forming rollers | GCr15, Quenching, hardness HRC56-62º |

| Forming Speed: | 12 meters / min |

| Main motor: | 5.5kw |

| Sheet Thickness: | 0.3 to 0.35 mm |

| Cutting mode: | Hydraulic automatic punching and cutting machine |

| Control mode | PLC |

The profile of Cross T grid Profile is here for your reference:

Metal thickness: 0.28mm

Length: 600mm, 1,200mm

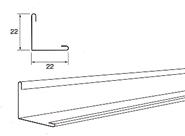

3. Wall angle roll forming machine:

Wall angle roll forming machine (Ceiling Angle Molding machine) consists of Single or Dual Head Type Un-coiler, Roll forming main machine, Hydraulic, Automatic Punching and cut-off Device, PLC Automatic Control Cabinet, etc.

The type of machinery is available with CL type (change-table-set) with pre-punching press for L – angle and W -angle with tab.

Parameters of wall angle roll forming machine:

| Line structure | Portal-type frame style |

| Forming Roller Stations: | 10 Stations |

| Forming Roller shaft: | φ36mm |

| Forming rollers | GCr15, Quenching, hardness HRC56-62º |

| Forming Speed: | 12 meters / min |

| Main motor: | 5.5kw |

| Sheet Thickness: | 0.3 to 0.35 mm |

| Cutting mode: | Hydraulic automatic punching and cutting machine |

| Control mode | PLC |

The following Wall Angle (Ceiling Angle Molding) Profile is as reference:

Metal thickness: 0.45mm

Length: 3,000mm

Features of ceiling system T grid machine:

- High-quality equipment with reasonable prices

- We have Quality Control to check every manufacture process, making sure that each product is up to standard.

- The machine is fully automaic and save your labor cost.

- The system controler PLC is highly accurate and easy to operate.

| D-coiler | Coil weight : 5 MT Max Coil width : 1250 MM Coil bore: 450 MM min, 510 MM max dia. Mandrel movement : Manually djusted Back Tension : Manually adjusted |

| Entry Gate | Entry gate will be provided for making sure to delivering sheet to roll former |

| Mill stands (Station) | The stands (GCr12MoV) installed on machine and their alignment can be easily done due to guide ways arranged on the bed of the machine. The mill stands will be arranged to locate shafts mounted on taper bearings. For different sizes or shapes ceiling channel, simply change stands manually or automatically |

| Main frame of machine | It uses 25mm thickness quality steel |

| Roll shafts | The roll shafts dia. 70mm will be manufactured from quality steel and will be keyed to locate tooling. |

| Control system | PCL computer or station |

| Counter | 1 set |

| Runout table | Quality steel |

| Drive | Gear or case of differential for high speed |

| Cutting Unit (Servo) | Flying track cutting saw |

| Hydraulic station |

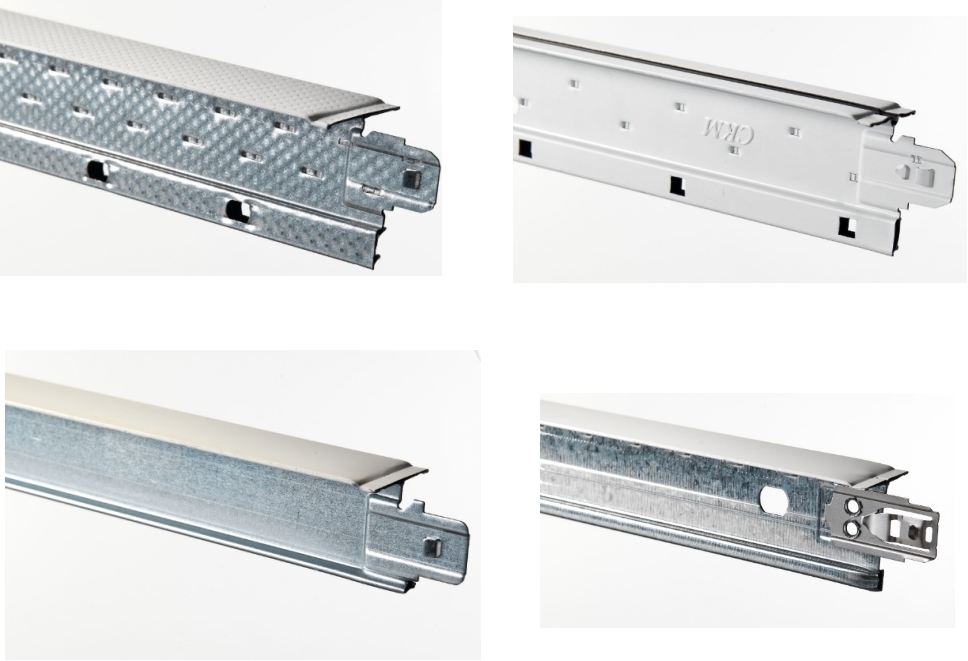

Here is a picture of elements of our machine for your reference:

Click here to watch the operation of ceiling system T grid machine.