C-type keel is a common light steel keel with a cross-sectional shape of “C”. C-type keel is one of the common light steel keels, mainly used for ceiling, partition wall and floor installation, widely used in building decoration, furniture production and other fields. C-shaped keel has high strength, light weight, easy construction, and good resistance to heavy pressure and stability.

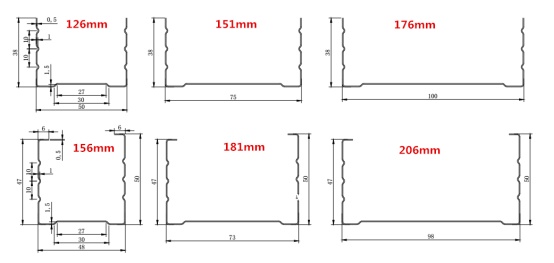

The profile drawing:

The pictures for the finished product:

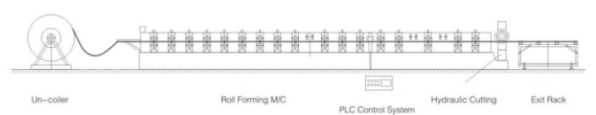

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the C-type translation keel machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

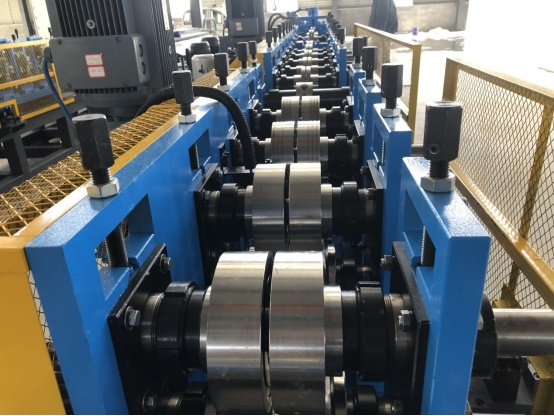

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the C-type translation keel machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Decoiler | 3T |

| 4 | Felt device | Available |

| 5 | Roller station | 14stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 40mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By Gear dual motor |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | Steel plate welded |

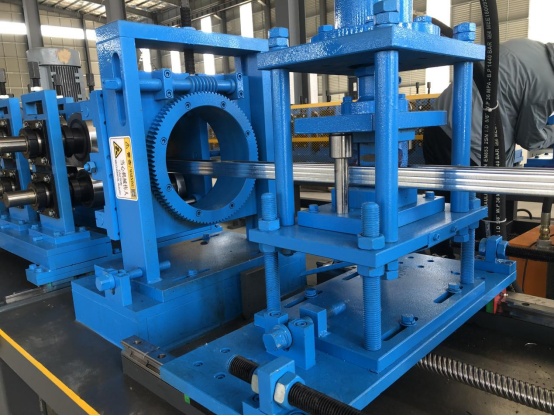

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 4kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the C-type translation keel machine:

1. Stable performance:

The C-type translation keel machine adopts full LCD screen operation and gear transmission to ensure a smooth and durable molding process without waste generation.

2. High production efficiency:

This device has a high production speed, such as reaching a production speed of 60 meters per minute.

3. Multifunctionality:

The C-type translation keel machine can produce various types of keels, such as C-type partition keels, which are suitable for decorative keel structures in indoor building decoration such as factories, office buildings, offices, large and medium-sized shopping centers, shopping malls, supermarkets, etc.

4. Diverse material selection:

The keel material can be hot-dip galvanized or aluminum zinc coated thin-walled steel plate, suitable for load-bearing and non load-bearing walls.

5. Design features:

The C-type translation keel machine adopts rolling or stamping bending thin plate forming, and the cross-sectional steel includes C-type, U-shaped, H-type, etc.

Some details of the C-type translation keel machine: