The main functions of the C Stud Roll Forming Machineinclude cutting, molding, and bending functions. It can conveniently and quickly cut keel materials, significantly improving production efficiency and reducing the significant time and labor costs required for manual cutting.

In addition, the C Stud Roll Forming Machine can press flat light steel materials into the required model and angle, ensuring the accuracy and consistency of the materials and improving the overall structural strength.

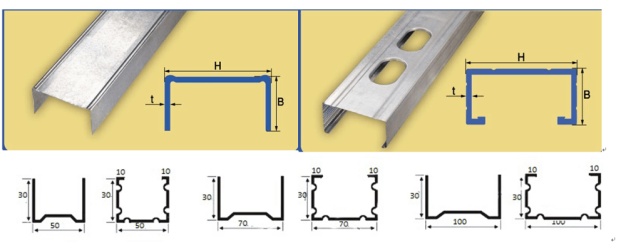

The profile drawing:

The pictures for the finished product:

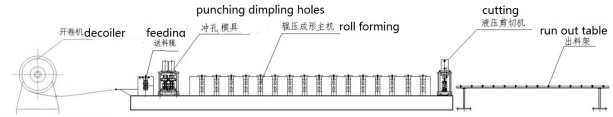

Production process:

Manual decoiler→Feeding material into machine→Punching the dimpling holes→Roll forming machine→Measure length→Hydraulic cutting→Finished Products

Packing list of the C Stud Roll Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the C Stud Roll Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.5-1.3mm |

| 3 | Decoiler | 3T |

| 4 | Felt device | Available |

| 5 | Roller station | 12stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 40mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By Gear dual motor |

| 10 | Motor power | 7.5kw |

| 11 | Machine frame | Steel plate welded |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the C Stud Roll Forming Machine:

1. PLC control: The equipment is equipped with multiple safety protections during normal production.

2. Bed design: Steel plate welded parts are used and tempered to eliminate internal stress and avoid deformation of the machine body.

3. Forming frame: Made of cast iron structure and tempered, with high strength and long service life.

4. Transmission structure: Adopting gearbox transmission to ensure the equipment operates at high intensity for extended periods of time and has a long service life.

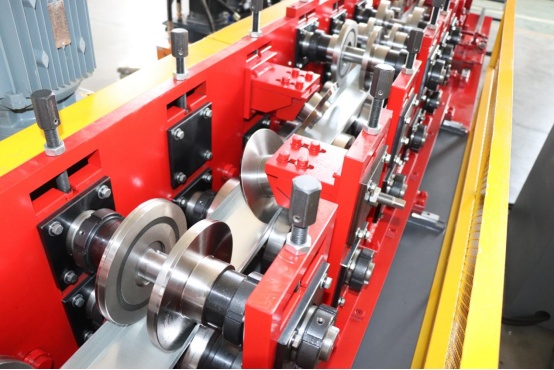

Some details of the C Stud Roll Forming Machine: