C purlin making machine is made to produce C-shaped purlins that fit various punching holes. Our C pirlin making machine can meet your different requirement by producing many sizes of C purlins. We have designed two operation modes, one is manual, and the other is automatic.

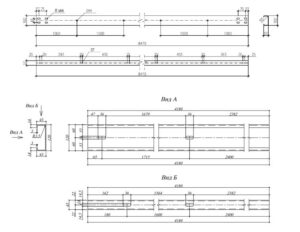

There some different profile drawings for your reference:

Finished product & C purlin making machine:

Features of C purling Machine:

- Working speed is around 15 to 25 meter per minute.

- Use the molding frame, the thickness of frame is around 35 to 45mm.

- Use the gearbox as transmission.

- Use the hydraulic shearing system.

Main components of C purlin making machine:

- Hydraulic Pre-cutting (used for cutting coil head and coil tail)

Function: Cut material head and tail to reduce waste.

Blade: scissor cutting structure, stable and convenient feeding.

Material: Cr12mov, Heat Treatment, and Shear all the way up to 3.0mm Steel Plate.

- Pre-Leveling Device

The In-feed Section of the machine allows for variations in sheet width.

Pre-Level Device with 4 over 3 shafts to remove the Coil-set.

Making sure the material is flat enough to be formed (or punched).

- Hydraulic Pre-shearing & Pre-punching device

On line Die-set LEAD screw drive for different web punching sizes, and the number of punching cylinders could be customized upon client needs(CUSTOMIZABLE).

Pre-shearing is used when changing the coil, manual control, only for cutting the first piece and the end piece of the sheet

Pre-cutting device, PLC control, purlin has bit open-up in both ends; panel length min 2.5m.

- Cold Rolling Mills

High Precision Servo Motor is adopted to ensure the punching accuracy.

One-button control to swap from C to Z, Z to C.

Changing WEB and FLANGE with auto PLC control,any within range.

Shaft Diameter:Φ75/95 mm .

Raw Materials: Cr12, Heat Treatment.

- Hydraulic Post Cutting

Screw adjustment to realize rapid switching of WEB size, to achieve different specifications of C/Z purlin shearing.

The cutting tool material is made of Cr12MoV after heat treatment, with high strength, which can better guarantee the cutting effect and the durability of the cutting tool.

Blanking size up to 8mm, Minimize the material wastes.

- PLC Control System

Fully automatic conversion control, Size: C to Z or Z to C

Specification: C100-C300/Z120-Z300

Fully automatic production: QUANTITY/ PRODUCT LENGTH/PUNCHING POSITION/ (UPTO 100 ORDER MEMORIES).

PLC(Siemens), Touch Screen (Siemens), Encoder (Omron), etc. Cut-to-length-tolerance≤±1mm

After-Sale Service

- The warranty is 24 months after the client receives the machine.Within the 24 months, we will courier the replacement parts to the client free of charge.

- We offer technical support for the entire life of our machines.

- We can send our technicians to install and train the workers in the clients’ factories with extra cost.