Automatic C Purline machine with Multi-punching is designed to make the C purline machine in various sizes with many types of punching hole. In the market, there are many types C purline machine, like CZ purline machine, Z purline machine, either in the manual adjustment way or the fully automatic method. Here the machine I share we designed for France, Various type C purline with the Multi-punching, the size adjustment by button control and by PLC control both, no need the manual work.

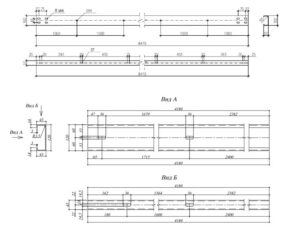

Take the following C purline drawing for your reference:

C Purline Finished Product:

C Purline machine Design:

Features of C purling Machine:

- Working speed is around 15 to 25 meter per minute.

- Use the molding frame, the thickness of frame is around 35 to 45mm.

- Use the gearbox as transmission.

- Use the hydraulic shearing system.

- Use the automatic stacker.

- The punching are before punching.

- The sizes are controlled by PLC or button control.

| C Purline machine Basic Parameters | |

| Forming station | 14 stations |

| Forming Rollers | GCr15, heat treatment and hard chrome-plated ,HRC55-58 |

| Main shaft material | S45C, heat treatment HRC42 Φ80mm |

| Leveling roller | 5 rollers |

| Pinching device | 2 Steps of pinching |

| Punching hole | Punching before forming |

| Cutting sheet | Cutting after forming, stop to cutting |

| Forming speed | 0-18m/min |

| Producing speed | 0-12m/min |

| Main motor power | 15KW, Chinese famous brand |

| Transmission system | 1.0 double line chains |

| Control system | PLC Siemens brand |

| Dimension(L×W×H) | Approx.10000×1400×1600 mm |

| Weight | Approx.9500kg |

Here are more details about the C purline machine for your reference:

- Use the gearbox as transmission:

2.Punching station with the energy accumulator:

With this energy accumulator, the punching will not stop and then the punching speed could be doubled.

3.Automatic stacker will help receiving the C purline orderly.

For the C purline machine, CZ purline machine, if you need more types, please contact us at any time.