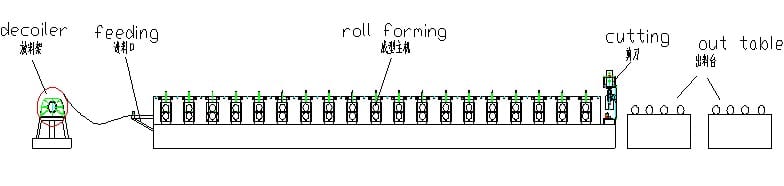

rocessing flow diagram of machine

Manual de-coiler→ Feeding material into machine → Main Roll forming machine →Measure length →Hydraulic cutting →Run out table

Material

Minimum Thickness 0.3mm

Max Thickness 0.8mm

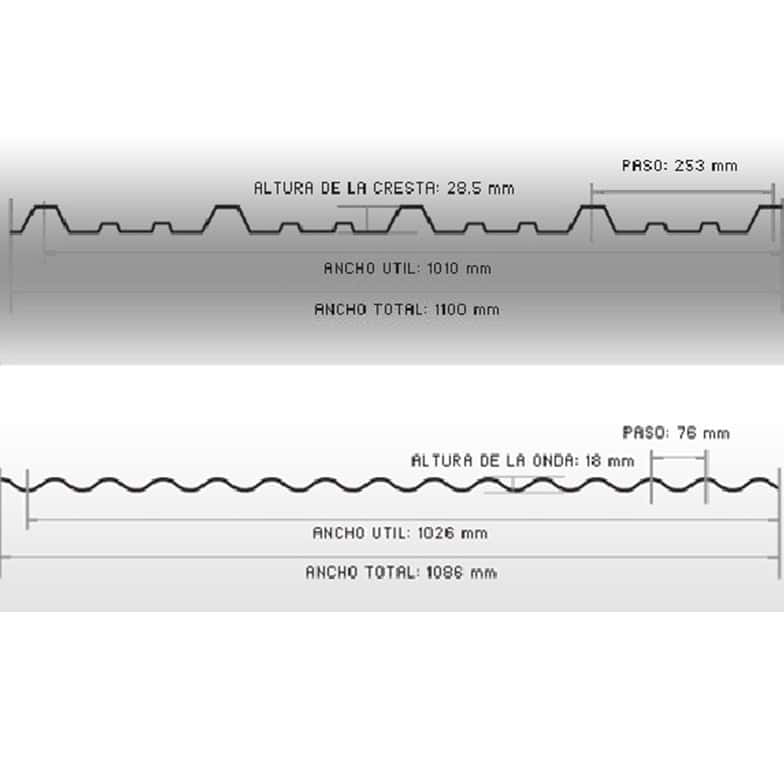

effective width 1100 mm /1026mm

Hydraulic Uncoiler Coil inner diameter 450-550 mm

Max coil out diameter 1300 -1600 mm

Carrying capacity 5 T

Entry Beach Put the raw material (steel plate) through the beach to manufacture and process,

it can guarantee that the products are neat, parallel and everything is uniformity

Please refer to the equipment regulation to know the function of locate dam board.

Main machine Forming steps 13rollers/15 rollers

Shaft diameter 80mm

Design type Middle Plate Structural

roller material 45# steel chrome plating chromium

shaft material 40Cr steel

Work speed 6-12m/min

Transport By chain

Type of cutting Hydraulic

Cutting tolerance ±1mm

Cutter Gcr12

Cutter quantity 2 set

Working pressure 40MPA

Feature Ensure stability, precision and cutting speed

Function Automatic cutting controlled by PLC. It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades Cr12 quenched

Power supply hydraulic power

Components It contains one set of blade, one hydraulic tank and one cutter machine.

Hydraulic Station

Power 4 kw

Hydraulic oil 46#

Components The system includes a set of hydraulic tank, a set of hydraulic oil pump, 2 hydraulic pipes. And 1 sets of electromagnetism valves.

Electric Control System 1.Adopted PLC, frequency converter, Delta from Taiwan to ensure high speed with stability, precision and lifetime.

If you need, we can change it other brand or little computer type for touching screen.

Weight About 6 ton

Dimension 8500 х 1650 х 1500 mm L x W x H

Main body color As required

Voltage 380v/50hz/3ph(or as required)

Spare cutting blade One piece for profile

Fuse 2 pieces

Relay 2 pieces

Travel switch 2 pieces

Solenoid valve 1 pieces