1100 tile water ripper glazed tile steel making roll forming machine is used to make the step tile in batch fully automatically. And this step tile is quite popular in European. Compared with the tradtional glazed tile making machine, this one the speed is faster and it is more stonger than the normal roofing sheet machine.Roof panel machine

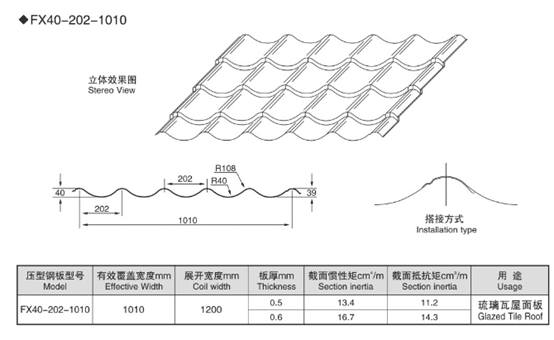

This is the drawing profile of glazed step tiles for your reference

Based on the 1100 tile water ripper glazed step tile, we design the machine like following:

Technical parameters:

| 1. carrying capacity | 6 tons |

| 2.Stype | Manual |

| 3.Coil material | steel |

| 4.Coil thickness | 0.3-0.8 mm |

| 5.Roller station | 17 station |

| 6.Roller material | Gcr15 quencing at 58 degree |

| 7.Shaft material | Gcr15 quencing at 58 degree |

| 8.Shaft diameter | 90 mm |

| 9.Machine weight | About 6.5 tons |

| 10.Machine size | 7.5*1.5*1.5 m |

| 11.Speed | 5-8 m/min |

| 12.Operate | Hydraulic cutting |

| 13.Blade material | Cr12 |

| 14.Operate | Chain transmission |

| 15.Chain size | 1 inch chain |

| 16.PLC brand | Taiwan delta |

| 17.Motor power | 7.5 kw |

| 18.Hydraulic pump power | 4 kw |

| 19.Voltage | 380V 50Hz 3phase |

| 20.Machine color | As ur need |

| 21.Machine language | Chinese and English |

1100 tile glazed step tile steel making roll forming machine is reasonable, the production is excellent, the equipment is easy to change and operate, the motor power is large, and the industrial control frequency conversion system is installed, which makes the machine run more smoothly and greatly improves the precision of production. The finished plate shape is more processed and beautiful.

Scope of application

A wide range of industrial and civil buildings, such as factory buildings, warehouses, hangars, stadiums, exhibition halls, theaters and other rooms and walls.