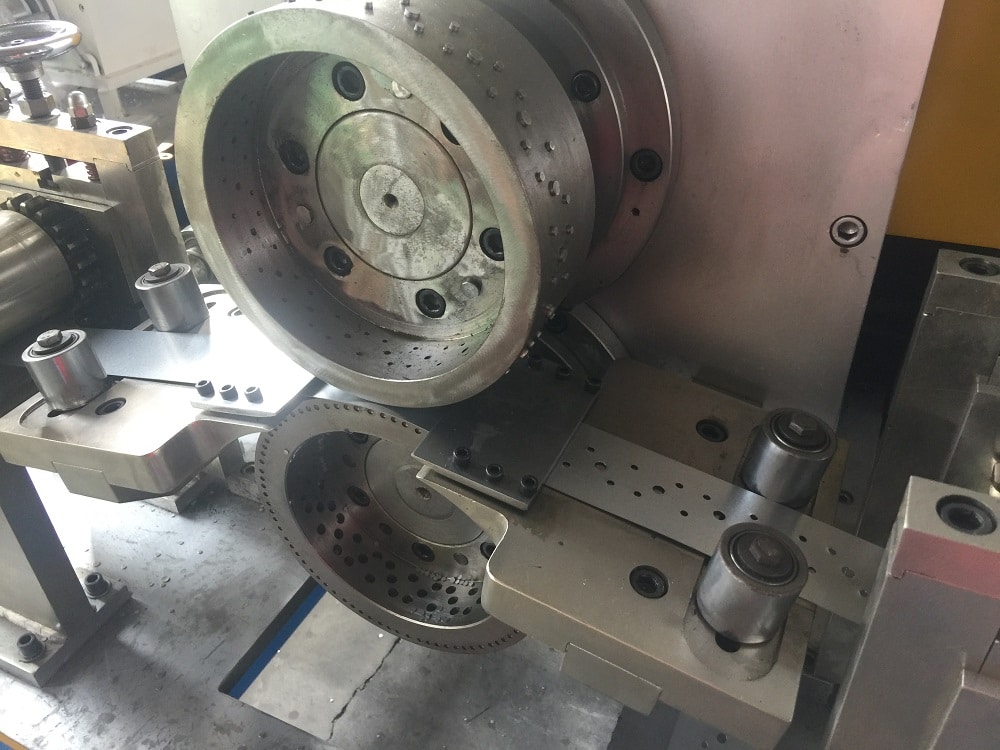

High speed rotary punching machine is a new developed punching machine, which can punch the metal sheet with high speed, which can reach 80-100 meters per minute.The structural of the meatl rotary punching machine is there are up rollers and down rollers with teeth and notching, high rotary running and punching. Holes diameter, holes center distance, holes shapes, it is determined by the rotary rollers molds.

HIgh speed rotary punching machine can be designed according to the requirements, such as the raw material steel strips width, thickness, holes pattern, holes center distance. Below i can introduce you a rotary punching line which designed to make the hoop iron. Whole line of rotary punching machine is including below parts: un-coiler, leveling, rotary punching, cut to legnth, receiving table or re-coiler.

Below are some specifications and pictures of the whole machine line, please check it. if you have any need of the rotary punching machine, please write me your requirements, we can design your perfect rotary punching line.

1 Thickness: 0.4-1.5 mm

Feeding width: 25 – 32 mm

For this strips specifications, the machine need work as below:

De-coiling,straightener,pre punching,cut to length,run out table, and recoiling.

2 Thickness: 1.5 mm

Feeding width, 25-300mm, for this situation, the machine work as below:

De-coiling,straightener, cut to length,run out table, and recoiling.

3 Automatic receiving table, which receiving 20 pieces, will shake off one time.

Automatic flip over (20pcs at a time) table

Simple decoiler

◆Function: expand and shrink manually which could expand fromφ480 to φ520 . It has the device to block the coils and prevent them from loosing.

Inner Diameter:450-550mm

Outer Diameter: max 1500mm

Max Coil width:300mm

Capacity: 1.5T

Servo precision straightening machine

◆It is controlled by servo electromotor and used to regulate for high speed feed and precise length control

◆The operation is done at the control table with programmable control.

◆Five roller straightening system: 2 roller configuration

◆Roller handling process: Raw material tempering-rough process-Hardened HRC55-60-finish machining

◆ Drive model: 1.5kw servo motor with precise decelerating transmission

◆Achieve the hydraulic necessary of the whole production line.

| perforating machine | Gcr12MoV quenched |

| Power of perforating machine | 4kw |

| The size of the holes | 3mm (hole sizes are 3mm & 6mm with specific spacing as sample) |

| The thickness of material | 0.4-1.5 |